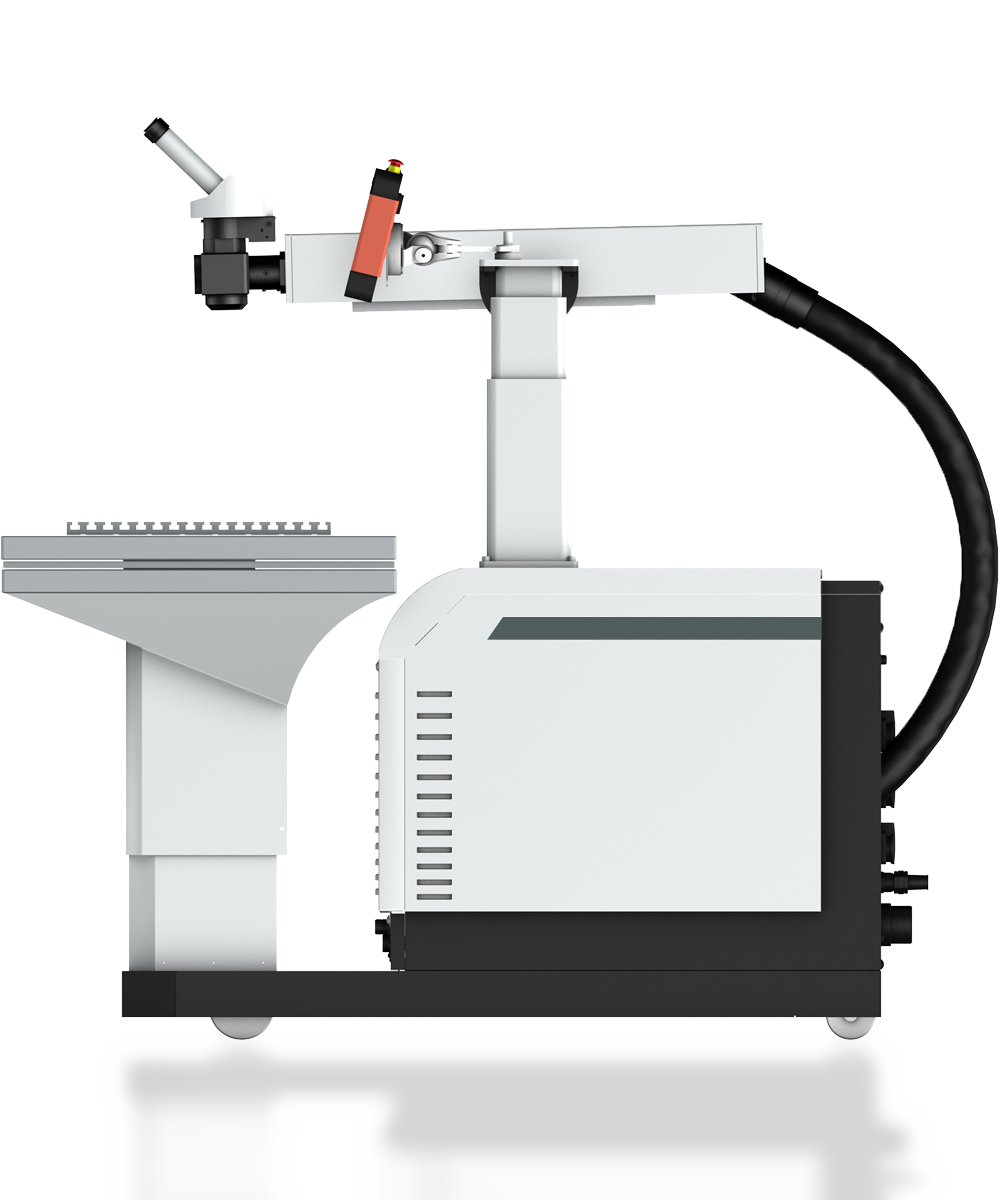

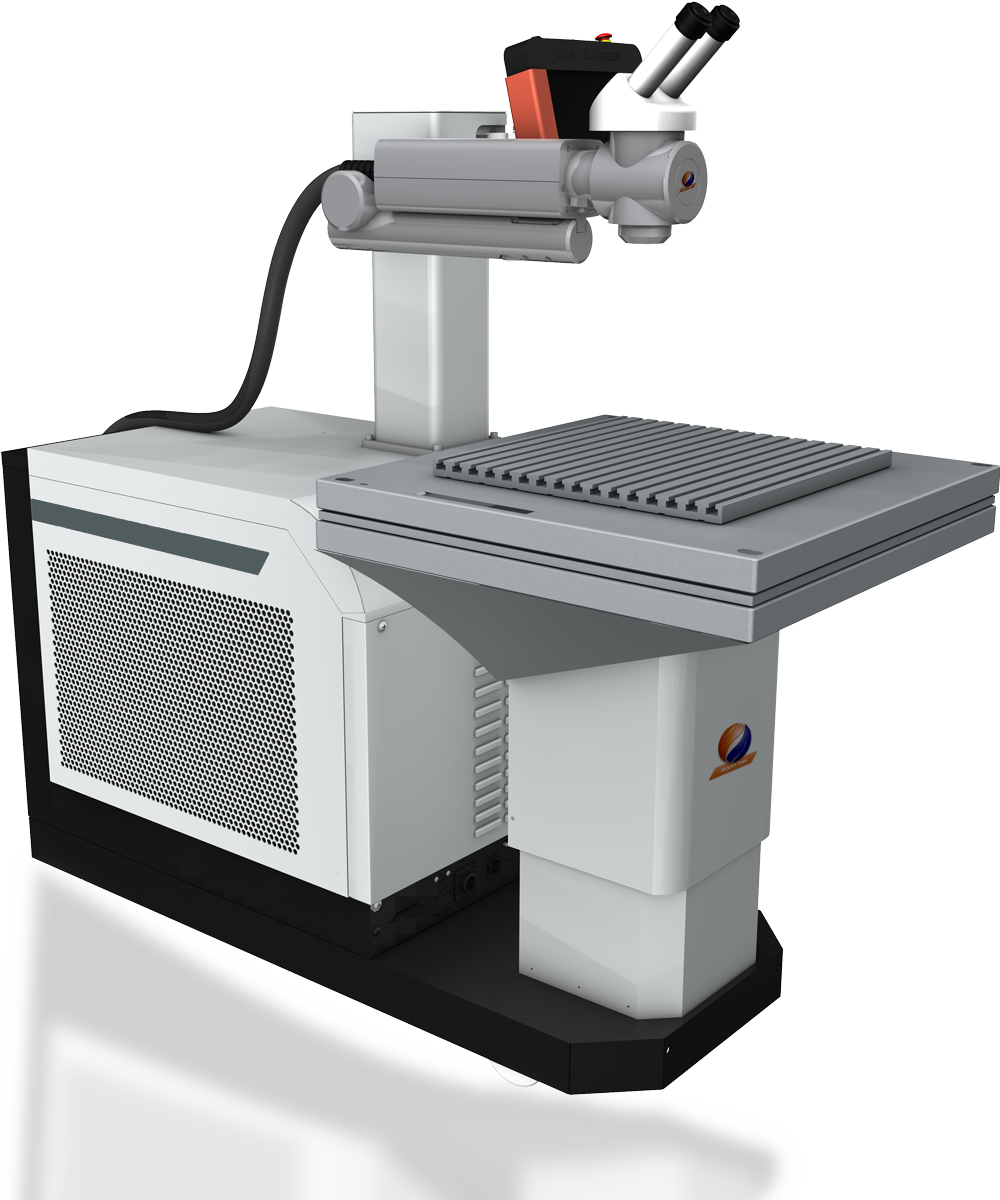

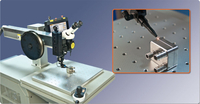

LRS EVO

Efficient with substance

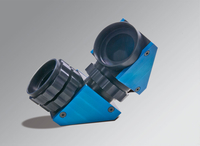

Intuitive laser technology for small to medium sized molds

Highlights

- Big rangeability

- Two Z axes

- Motorised x/y and Z travel

- Teach-in function

- Up to 350 kg table load capacity

- Compact size

- Simple operation via controller

- Compatible with CAD / CAM software solution MTLAS SUITE

- Compatible with the powder feeder and powder nozzle

Achieves a lot and asks for little

Inspirations of our customers and several years of development led to a complete redevelopment of this laser welding system. The result is a mobilelaser welding system that sets new standards for open laser workstations. In addition to the comfortable operating features, designed with practical use in mind, a wide range of innovations support semiautomatic processing. Continue reading to learn about all the new developments and form your own opinion.

Ergonomics without compromise

We have enhance the LRS EVO laser system to satisfy versatile requirements in tool and die making and in other industries as well. Intuitive operation – fast and efficient. With this system no wishes are left unfilled in the processing of small to medium die sizes since extensive accessories can expand your welding capabilities for both simple and complex laser welding tasks. In designing this system, we placed great importance on user-friendliness, ergonomics and cost-effectiveness.

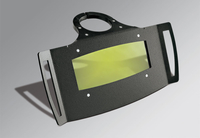

Optional: Operating via MTLAS SUITE

The MTLAS SUITE from OR Laser is an unprecedented new CAD/CAM environment for planning nearly all facets of laser processing: marking, engraving, cutting, welding, cladding, and powder-based additive manufacturing processes.

This is the first and only comprehensive software for industrial laser applications that is actually able to read and process all proprietary file formats and control all existing laser systems.

The MTLAS SUITE is excellently suited for supporting and planning processing strategies. The software supports the most popular 3D CAD file formats including STEP and IGES. The system also doubles as a tool for classic welding and marking tasks as well as powder-based laser cladding (also for depositing multiple layers).