DIODELINE

Diode-pumped Laser

The innovative laser technology for small to medium-sized shapes

Other highlights

-

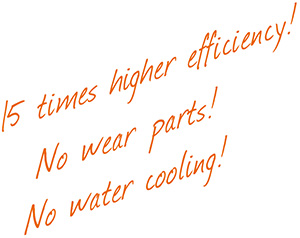

Very high efficiency of over 20 %

(electrical to optical) - Low power consumption in comparison to lamp-pumped Nd:YAG lasers

-

A simple power outlet is sufficient!

(230 V / 16 A / 1 phase) - Maintenance-free operation

- Long life of the pump diodes

-

Can be operated in pulse and cw mode

(continuous line) - Excellent, stable beam quality

- Small and flexible laser head

- Compatible with CAD / CAM software solution MTLAS SUITE

- Compatible with the powder feeder and powder nozzle

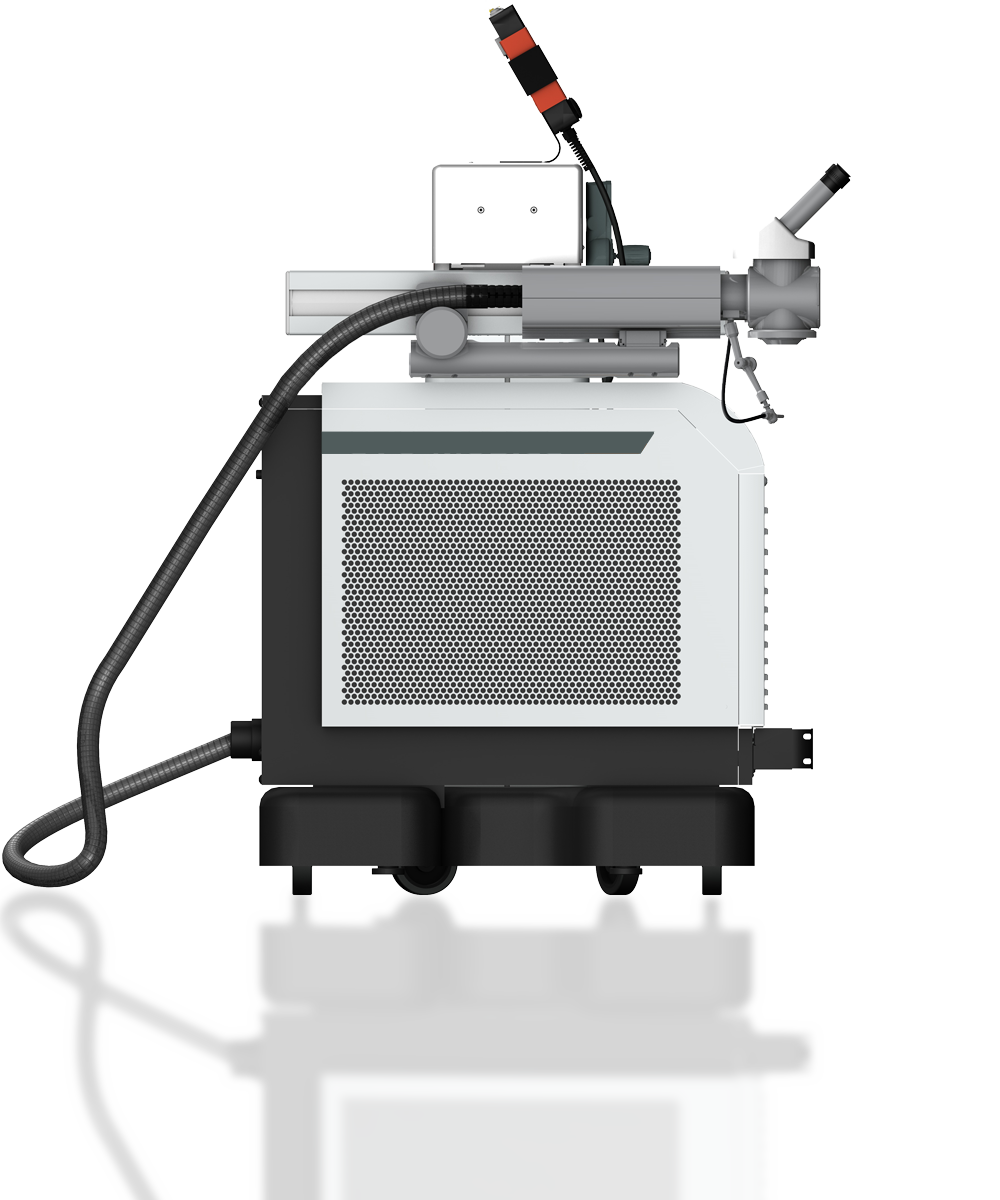

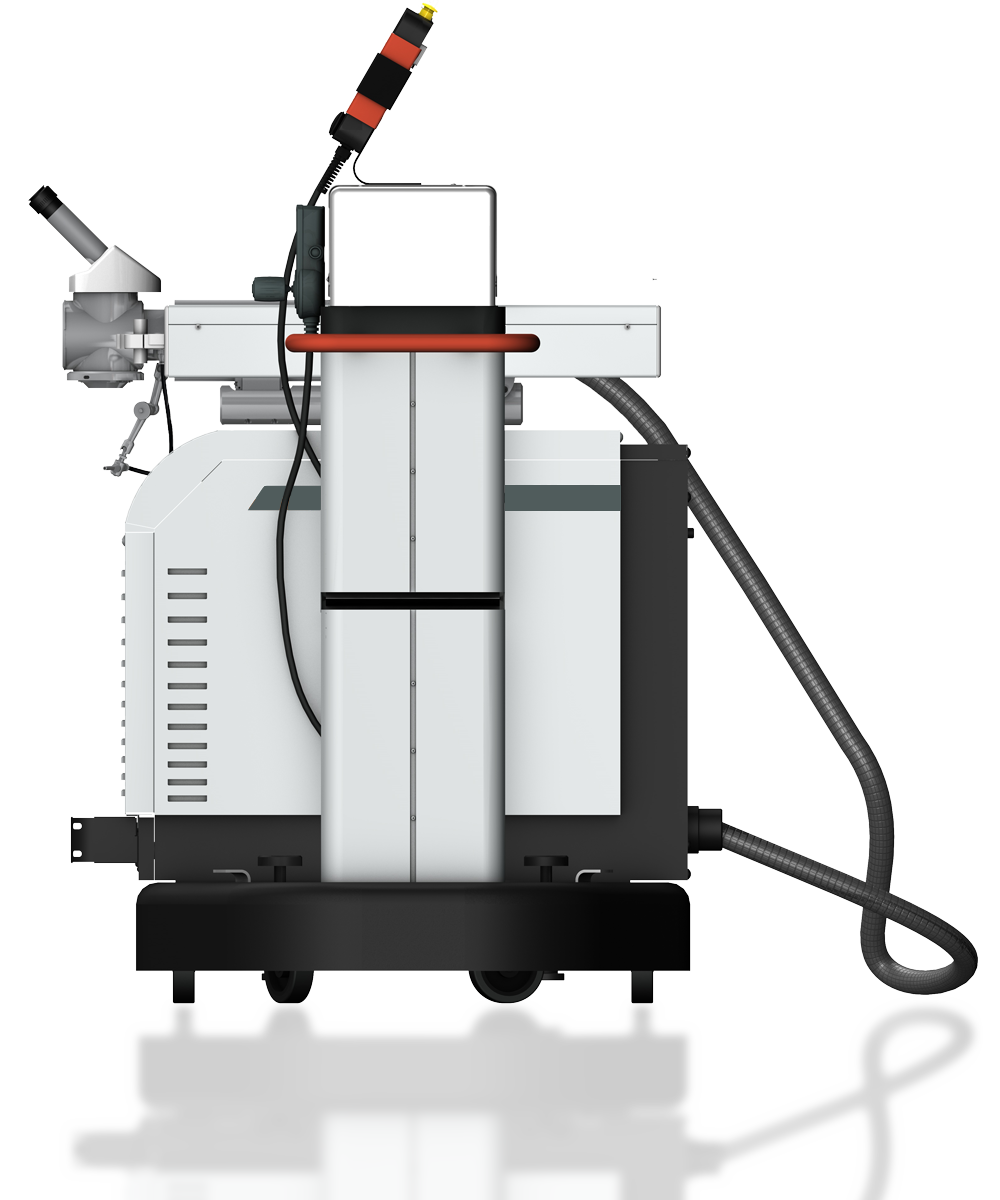

Diode Line – the diode-pumped laser

With the DIODE LINE concept, MT Laser enters a new dimension in the field of laser material processing through the use of diode-pumped laser systems. The new concept impresses by offering a number of key advantages over conventional flashlamppumped systems. In addition to the compact design and the extremely long life, diode-pumped laser systems are characterized by their 15 times higher energy efficiency. This not only saves cash, but also provides a valuable contribution to the protection of the environment. A high-voltage connection is no longer required! A normal 230 V outlet is sufficient for operation of the laser system. As there are no wear parts, the system operates practically maintenance-free. The system further convinces through its excellent beam quality even with very small spot sizes down to 50 μm. Thus even the most demanding welding jobs present no problems for the new system. MT Laser offers systems with peak performances up to 3 kW (300 W mean power) with pulse lengths from 0.1 ms to 50 ms at 0.1 to 100 Hz.

Comparison with conventional laser welding

| Comparison |

STANDARD INSTALLATIONS (ND:YAG LAMP-PUMPED) |

DIODE LINE (DIODE-PUMPED) |

|---|---|---|

| Mean power (pulsed) | up to 300 Watt | bis 300Watt |

| Mean power (CW) | -- | 250 Watt |

| Efficiency (electrical - optical) | ca. 3 % | > 20 % |

| Mains connection | 400 V / 16A / 3 phases | 230 V / 16A / 1 phase |

| Max. power consumption | 15 kw | 3 kW |

| Max. pulse duration | 20 ms | 50 ms |

| Max. pulse frequency | 20 Hz | 100 Hz |

Lens recognition

The innovative design of the laser welding head allows the use of different focusing lenses with different focal lengths with the system. The focal length is coded electronically on each focusing lens. The welding system automatically recognizes which focusing lens is being used and accurately displays the actual spot size to the user in the control system. Depending on the lens being used, the spot size can be adjusted almost continuously via an electro-mechanical beam expander.

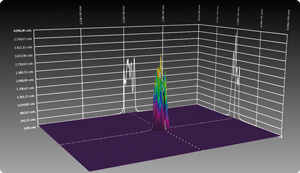

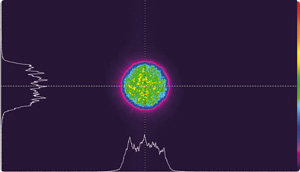

Beam characteristic

The beam quality of the laser systems is described by the key indicator, beam parameter product (BPP), and it essentially defines the ability to focus a laser beam. Thus a smaller BPP value indicates a better focusing ability. The smallest theoretical value with a wavelength of 1064 nm is 0.339 mm x mrad. The BPP value of our lasers starts at 1.4 mm x mrad and makes focus sizes of 50 pm possible.

Below, a table of BPP values for different glass fibers:

für unterschiedliche Glasfaser:

Faser: 50 μm ⇒ BPP = 1 – 2 mm x mrad

Faser: 100 μm ⇒ BPP = 2 – 5 mm x mrad

Faser: 200 μm ⇒ BPP = 5 – 15 mm x mrad

Beam profile of a 200 pm fiber, focused at a focal distance of 100 mm.

Beam profile of a 200 pm fiber, focused at a focal distance of 100 mm.

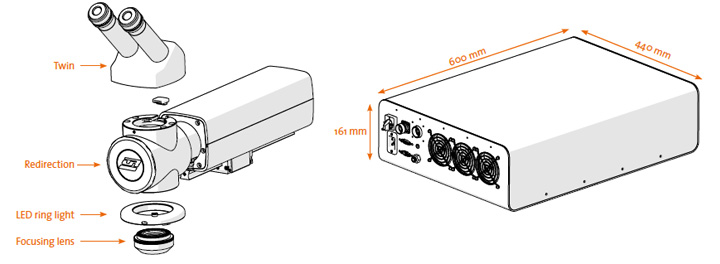

DIODE LINE as OEM Modul

The DIODE LINE OEM is designed as a module for installation in a system, a production line, or a manual workplace. The module is suitable for machine builders and integrators who want to integrate the laser into their system via a simple interface. The module can be used in a variety of ways because of its compactness and flexibility. This module includes an external controller that can be used to control the laser and to set and store the laser parameters. External control systems can communicate with the DIODE LINE OEM module via digital and analog interfaces. In this way, important parameters like the laser power can be specified externally or even individual laser pulses can be set.

Dimensions: Width 440 mm x height 161 mm x length 600 mm,

weight: Box 6g kg and resonator 7 kg net

Operation via touch screen

The 10” touch screen offers you access to all parameters and countless options to make important settings, which can also be stored directly. The stored data can be accessed at any time.

Optional: Operating via MTLAS SUITE

The MTLAS SUITE from OR Laser is an unprecedented new CAD/CAM environment for planning nearly all facets of laser processing: marking, engraving, cutting, welding, cladding, and powder-based additive manufacturing processes.

This is the first and only comprehensive software for industrial laser applications that is actually able to read and process all proprietary file formats and control all existing laser systems.

The MTLAS SUITE is excellently suited for supporting and planning processing strategies. The software supports the most popular 3D CAD file formats including STEP and IGES. The system also doubles as a tool for classic welding and marking tasks as well as powder-based laser cladding (also for depositing multiple layers).

Description of the system components

Many sectors, always ready for use: LRS EVO DIODELINE

Medicine

Implants for invasive transplantation

Implants for invasive transplantation

Aeronautical engineering

Engine components for aviation

Engine components for aviation

Electronics

Spot welding of a keyboard

Spot welding of a keyboard