Precision Laser Cutting

Laser cutting is a thermal cutting process for panels and bodies made of a wide variety of materials. Even complicated 3F geometries and contours can be produced precisely and quickly with laser cutting. Laser cutting differs from conventional processes such as punching in that small series and individual parts can be produced economically and cost-effectively when the right industrial laser cutting technologies are used.

CAD/CAM systems support specifications for the cross section, thus allowing high material utilization in precision laser cutting. The high accuracy of the cut is another advantage of laser cutting over other cutting processes and systems. With the selection of a suitable laser, everything from a joint of a few micrometers on medical components to a clean cut in thick sheet steel can be realized. This makes it possible to use laser cut service in a large number of different manufacturing applications and for many different customized products and objects.

As working with laser cutting is contact-free and force-free, any thermal stress is caused only by the laser energy. As a rule, the cut edges created are clean and require no finishing when precision laser cutting is used for professional applications.

Advantages at a glance

- Cutting of different material types and thicknesses

- Pinpoint accuracy, precise energy input

- Contact-free, force-free processing

- Minimal thermal material effect

- Kerfs of a few micrometers are possible

- Shorter time required for rework

- High automation and welding speed

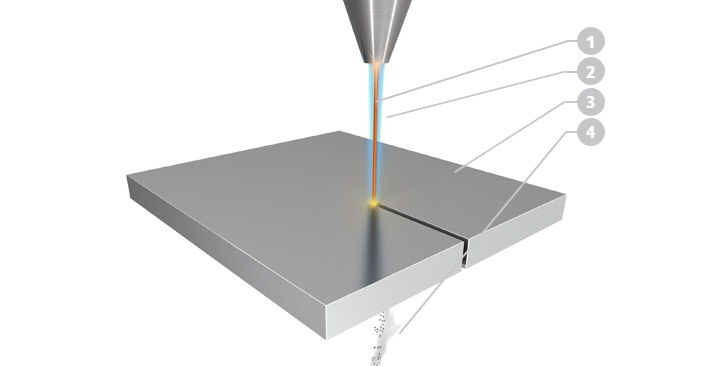

With this illustration, you can see the process of laser cutting at work

1: Laser beam 2: Cutting gas 3: Work piece 4: Melt

Laser cutting is divided into three different processes

- Fusion cutting

- Oxygen-assisted cutting

- Sublimation cutting

Precision Laser Cutting Equipment and Systems

We have a number of specialized laser cutting systems available that are well-suited for industrial laser cutting applications of every shape and size.

Check out our large catalog of equipment for sale, and feel free to contact us with any questions about the laser cut service that would best meet your specific needs. Trained customer service experts are standing by to help you choose the professional equipment that’s right for you.