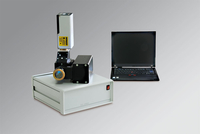

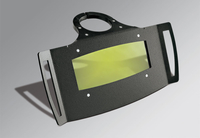

EVO MOBILE

Open to more flexibility

Mobile and compact laser welding systemfor open laser workstations

Highlights

- Compact size

- Simple operation via Touchscreen

- Autoweld

- Intern Videofunction

- High Pulse peak power

- Compatible with CAD / CAM software solution MTLAS SUITE

- Compatible with the powder feeder and powder nozzle

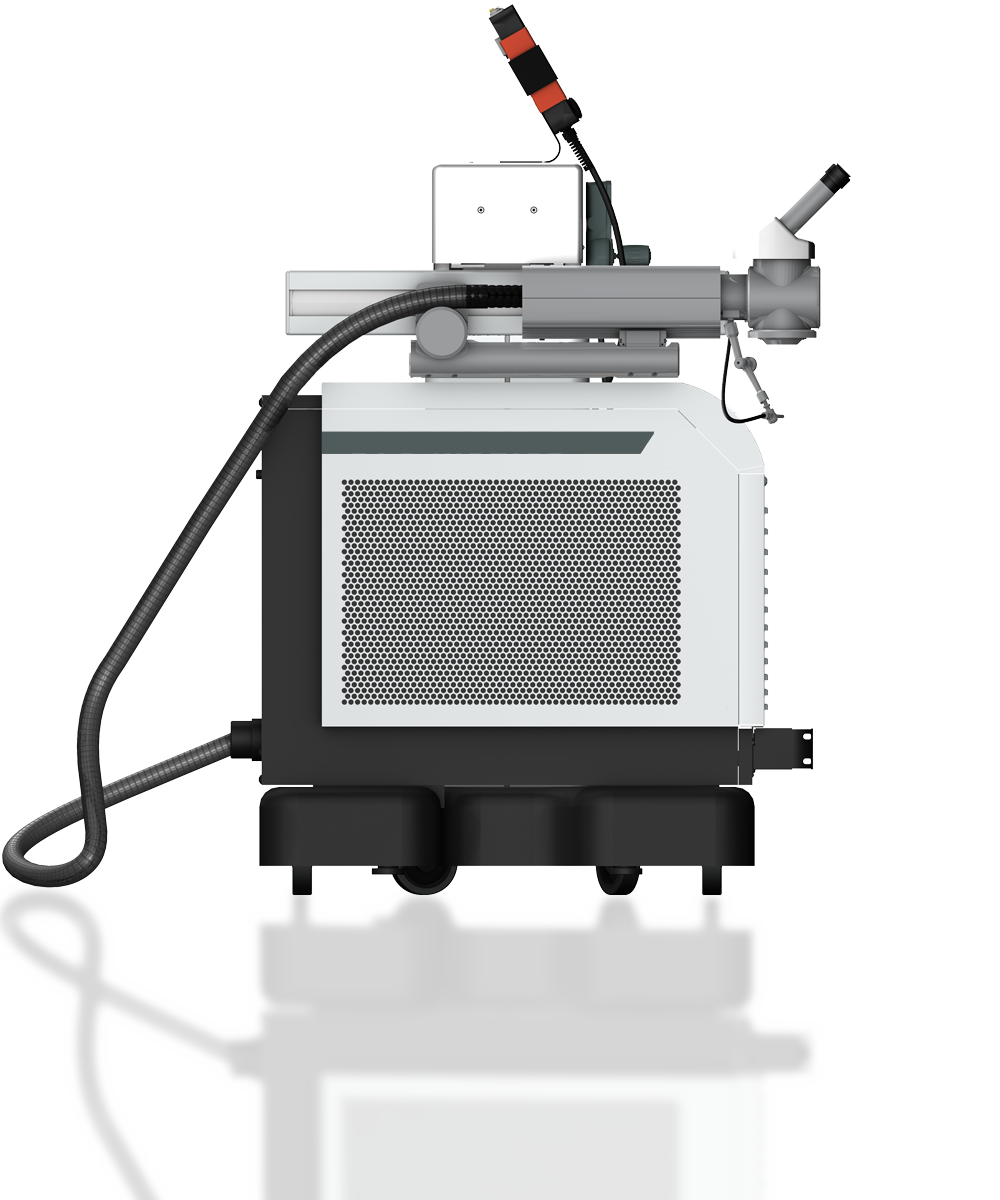

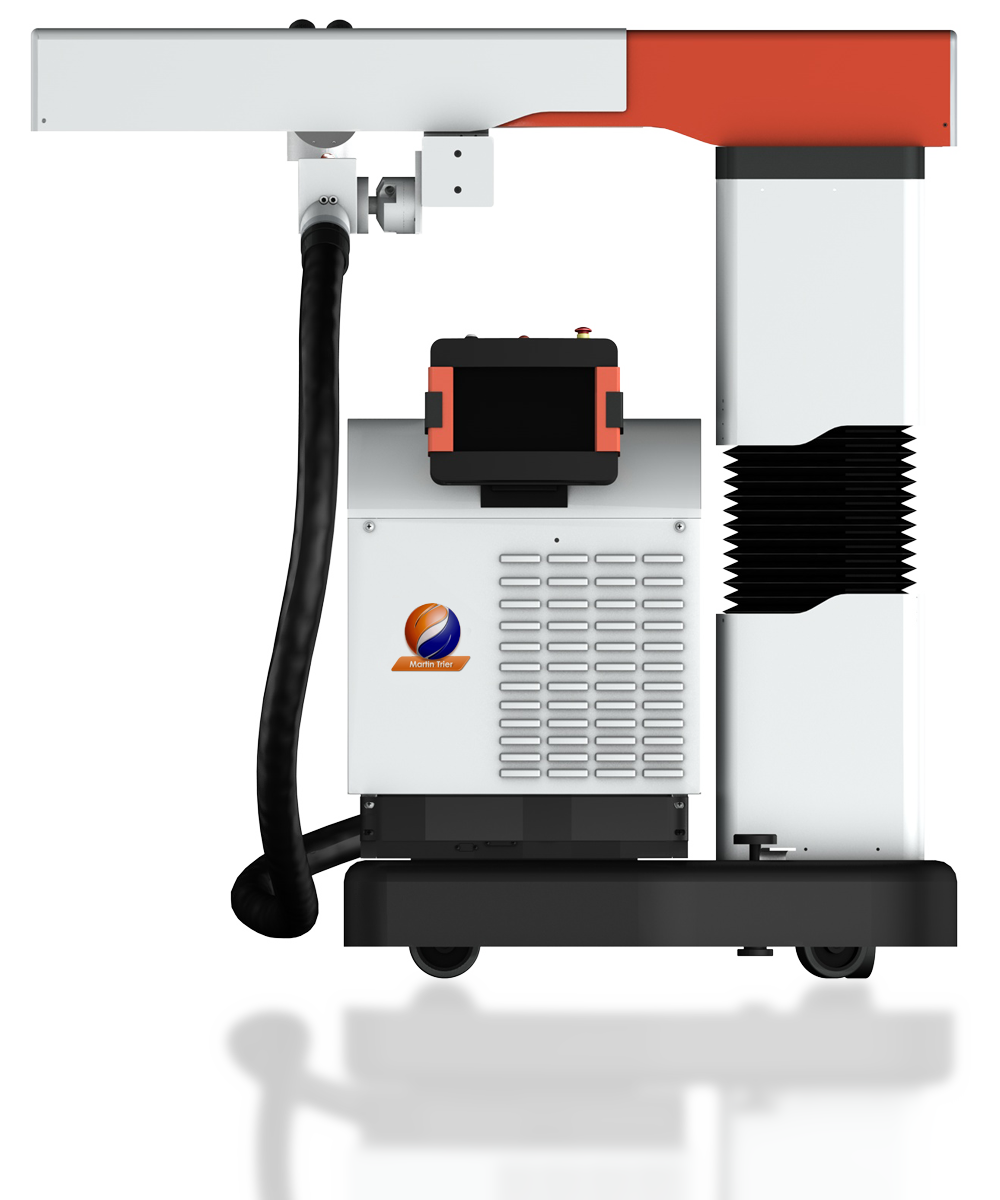

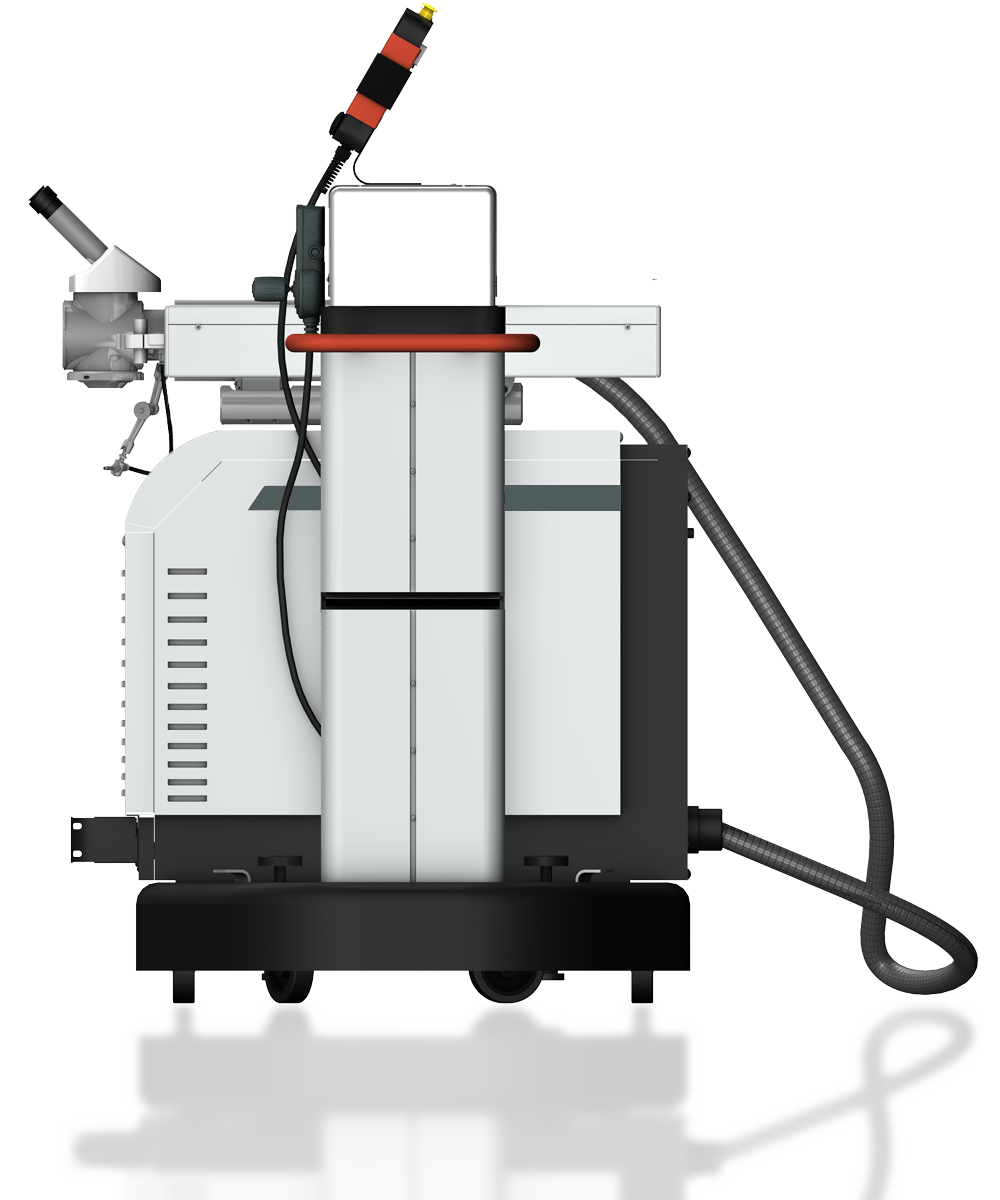

The EVO Mobile laser system

Inspirations of our customers and several years of development led to a complete redevelopment of this laser welding system. The result is a mobile laser welding system that sets new standards for open laser workstations. In addition to the comfortable operating features, designed with practical use in mind, a wide range of innovations support semiautomatic processing. Continue reading to learn about all the new developments and form your own opinion.

The added plus

Numerous useful aids are integrated for improving productivity. For example, the auto weld function allows the learning of geometric figures (points, circles, polygons) and the further processing of these surfaces with predefined welding parameters. This allows for a significant increase in productivity.

Another innovation is the option of rotating the coordinate system freely in space. This offers the user the ability to define an inclined plane in space as the processing surface, making welding significantly simpler for the user.

Completely new processing capabilities

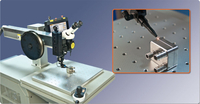

This new development has produced a laser system that sets new standards in the area of processing options. Small and compact but still with large traverse distances, it can be quickly readied for use and is extremely precise in order to meet the rising requirements of users such as service providers or tool and die makers.

The electromagnetically-controlled swivel arm can be extended like a telescope from 800 to 1500 mm and swiveled around its own axis. The traverse distance of the controlled axes is 700 mm in the x-axis and 400 mm in the y-axis. Vertically, the laser system can also traverse 400 mm in the z-axis. In other words, every laser welding process can be performed without constant repositioning or re-adjusting of the axes.

Ultra compact

The compact height of only 110 cm also allows for easy transport of this fully mobile laser system in a mini van or small truck and is setting new standards by significantly extending the reach compared to previous laser systems. The laser beam is directed to the welding position within the realm of millimeter precision. The minimal setup and takedown time as well as the long axis traverse distances of the EVO Mobile minimizes the total amount of work when processing tools and dies.

Ultra flexible

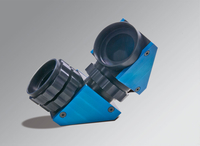

The EVO Mobile is extremely easy to use and can be held in a stationary position with the stabilization brakes. Movement of the axes allows for very long traverse distances and is also controlled via the joystick. This allows the welding position to be set with absolute precision down to 0.1 mm. With optical extensions and 360° swivel optics capabilities no angle will remain hidden.

Control via touchscreen

Via the 10“ touch display all parameters are accessible and there are reams of possibilities to adjust important settings which can also be stored directly. Saved data can be accessed anytime.

Optional: Operating via MTLAS SUITE

The MTLAS SUITE from MT Laser is an unprecedented new CAD/CAM environment for planning nearly all facets of laser processing: marking, engraving, cutting, welding, cladding, and powder-based additive manufacturing processes.

This is the first and only comprehensive software for industrial laser applications that is actually able to read and process all proprietary file formats and control all existing laser systems.

The MTLAS SUITE is excellently suited for supporting and planning processing strategies. The software supports the most popular 3D CAD file formats including STEP and IGES. The system also doubles as a tool for classic welding and marking tasks as well as powder-based laser cladding (also for depositing multiple layers).

One-hand operation via joystick

Along with the display, the joystick functions are the central operating element. Traverse speed, axis direction and more can be controlled and executed with the joystick directly. This increases efficiency during welding since modifications can be made directly during the welding process rather than only via the display. Path data can also be programmed directly with the joystick.

Welding made easy thanks to coordinate transformation

While repair or welding of large and bulky shapes used to be a considerable challenge even for experienced welders, the EVO laser welding systems with the innovative coordinate transformation now provides the perfect solution. Surfaces and edges which are not parallel to the axis can now be processed easily.

The coordinate axes are defined by three points, and with simple operation of the joystick in one direction, the EVO laser welding system executes synchronized movement of all three axes parallel, for example, to the mold edge. The result is optimal and manual focusing and re-adjustments are no longer required.