Electrotechnology

Major advantages in comparison to conventional methods

Electrical engineering

Electrical engineering

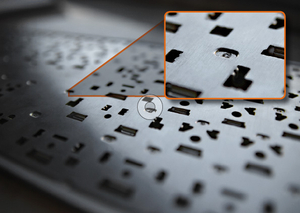

Nowadays laser applications are an integral part of the electronics industry. Lasers weld, cut and label all sorts of parts, components and end products consisting of different materials.

Plastics in particular but also copper and ferrous alloys are being used frequently.

At present, lithium batteries are seen as one of the most powerful batteries. For a long life, they must be hermetically sealed. This is ensured by welding lid and can by means of a laser. For economy, the material used most often for this is galvanized sheet steel. Welding with a laser is extremely straightforward.

For the production of lithium batteries in particular, safety rules in regard to the handling of water must be observed for industrial use within production. For example, use of water-cooled laser welding optics is not permitted because of the high reactivity of lithium with water.

For this reason,MT laser offers lightguide optics with passive cooling. This makes it possible to realize a safety distance from the laser source to the welding area without problems. This also allows integration into already existing production plants.

The automatic focusing of the laser beam also makes it possible to compensate for very small deviations in the shape of the component during welding. This also guarantees consistent welding quality.

MT laser systems are multifunctional, easily automatable and ensure high efficiency and quality. Especially the fabrication of products in high quantities benefits from that. In terms of speed and precision the laser has major advantages compared to conventional techniques and offers the user new processing options all the time.