Spot, seam, and direct welding

Spot, Seam, & Direct Welding

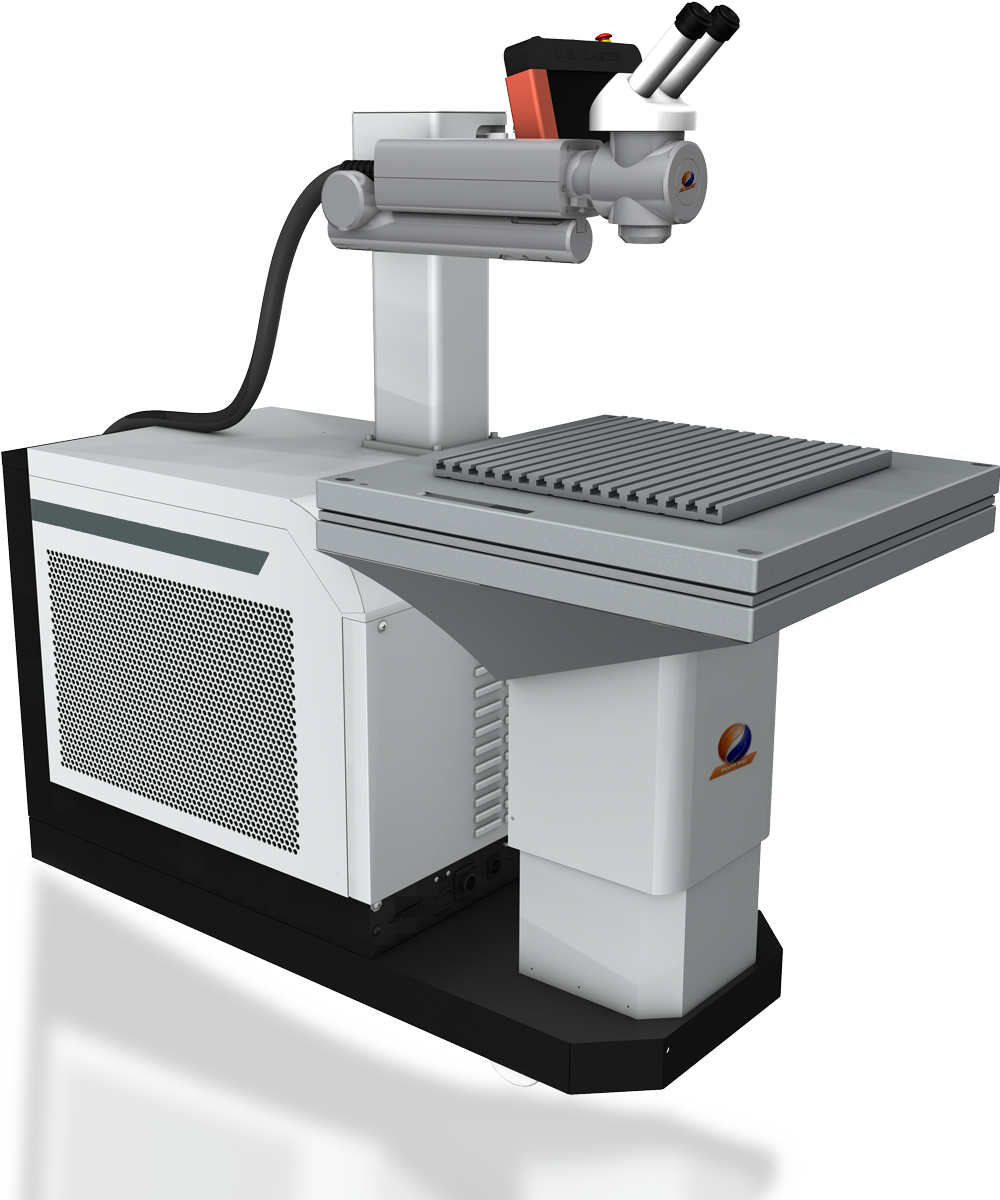

Laser spot welding, laser seam welding, and direct welding are three highly useful and slightly differing applications of the latest laser technology. Each function is possible with specialized equipment. Of the cutting-edge laser units from MT Laser, ten different models are recommended for spot, seam, and direct welding applications.

By selecting among the laser spot welder and laser seam welding units available from MT Lasers, you can ensure a professional finish, whatever your welding needs. Each system for sale from our catalog has a slightly different profile, making it ideally suited to a different area of manufacturing or industrial production. The versatility of our more sophisticated units allows highly customized performance, whether you’re more focused on laser seam or laser spot welding.

Spot and Seam Welding With Lasers

As the names suggest, spot and seam welding refer to welding functions applied to a single point or along a line. By setting a laser spot welder to a high welding speed and an extremely narrow weld geometry, the welder can produce extremely fine spot welding. Alternately, you can adjust the unit to weld on the continuous wave mode, welding with several kilowatts of power. The ideal welding speed for spot or seam welding projects varies according to the particular laser model, the laser power setting, and the material type.

Direct Welding With or Without Filler Wire

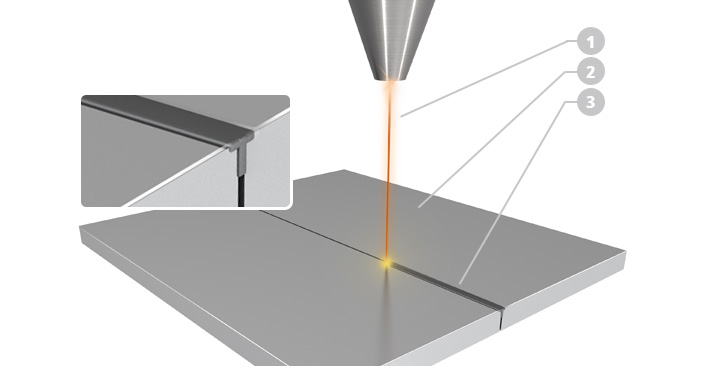

In direct welding, the welding head is positioned directly above the spot or line you wish to weld. This process has the advantage that the laser beam can always beam into the workpiece at the angle specified in advance. Optional accessories like filler wire and inert gas can be applied directly on the welded joint. The welding movement is powered by the unit’s drive shafts.

Depending on the welding task, the work stroke to the weld is accomplished either by the processing optics or by the workpiece. For maximum flexibility, most of the welding installations for sale from MT Laser have more than three shafts. Direct welding can be done in either pulse or in continuous wave mode.

1: Laser beam 2: Workpiece 3: Weldseam