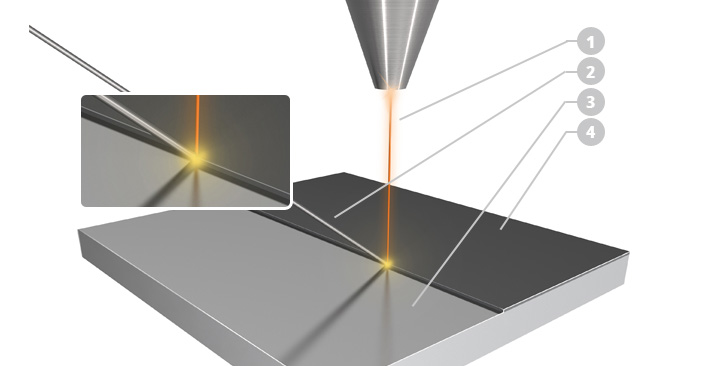

Laser cladding with wire

In this process, the laser beam melts the wire and the base metal, the melt bonds permanently and resolidifies until a small rise remains. When the individual welds overlap precisely, the desired shape is applied bit by bit.

Laser cladding with wire is used for the repair of components and functionalizing of surfaces. This process is particularly economical, clean, and rework is limited to a minimum. Various welding wires are available as filler materials. This makes it possible to apply material of the same type or to create functional layers according to the requirements for the coating.

1: Laser beam 2: Wire 3: Work piece 4: Application

The limitations of laser welding

| Material type | Carbon % | Thermal treatment before welding | Polish | Texture after weld |

| 1.2311 / P20 | 0,4 % | No | Yes | Yes |

| 1.2767 | 0,45 % | No | Yes | Yes |

| 1.2379 / D2 | 1,55 % | No | Yes | No |

| 1.2344 / H13 | 0,4 % | No | Yes | Yes |

| 1.2083 / S136 | 0,42 % | No | Yes | Yes |

| 1.2842 / O2 | 2,1 % | Yes | No | No |

| AlMg3S:0,5 | No | No | No |