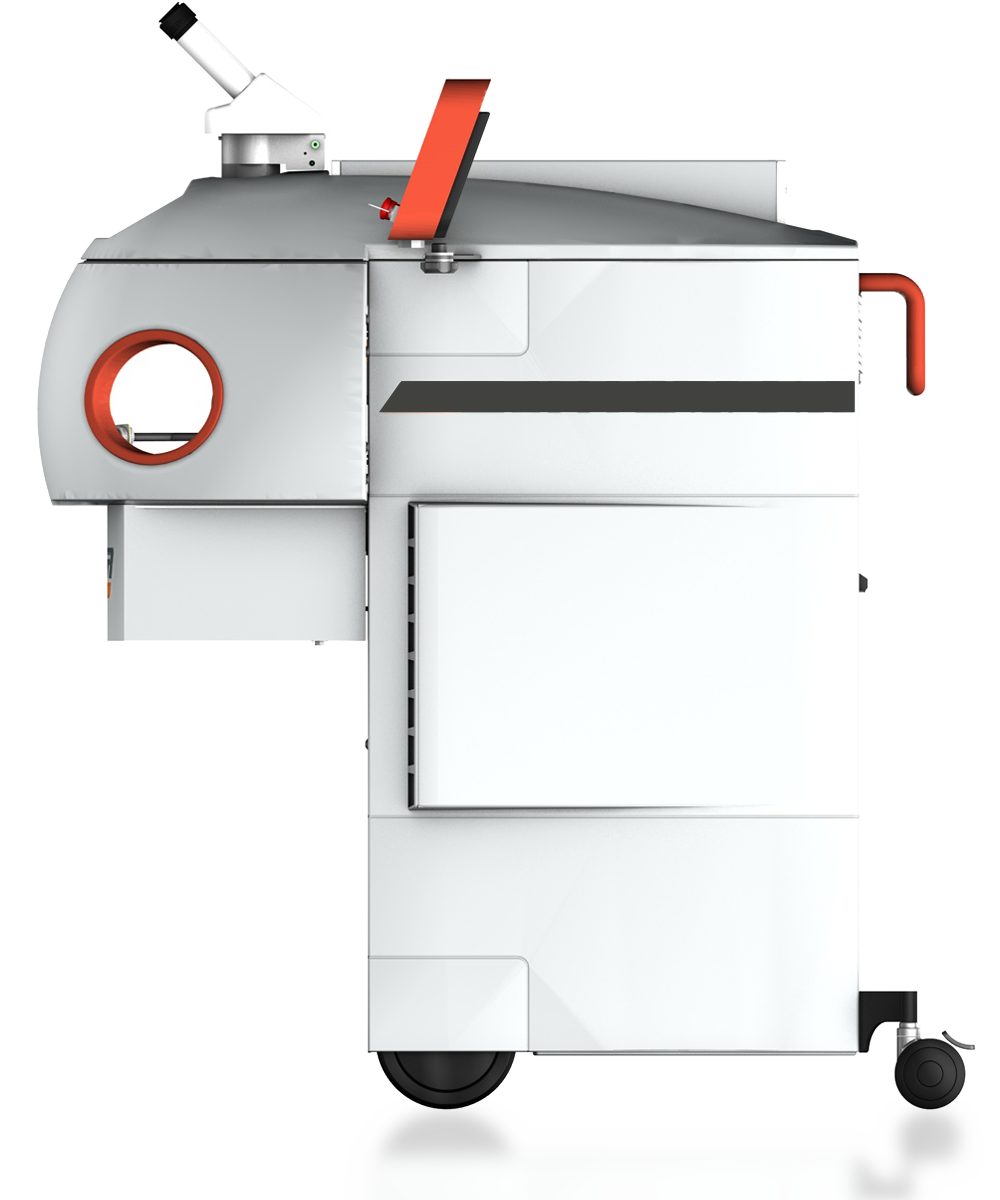

PICCOLASER

Brilliant achievement in practice

Laser technology for dental technicians and jewelers

Highlights

- Small, Mobile, Powerful

- High pulse peak power

- Joystick control of all functions

- Motorised travel in x/y/z axes

- Direct laser beam source

- Ultimate flexibility

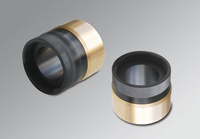

Compact, mobile and yet strong

Thanks to its high level of precision, laser welding equipment is already being used on a regular basis in today´s in the aerospace and automotive industry as well as for tool and mold making. However, its ability to handle extremely small details also makes it the ideal tool for Dental Technicians, Goldsmiths and Jewelers. MT Laser has developed a particularly compact piece of laser equipment especially for this target group: the Piccol aser. Finally there is a piece of equipment that combines the toughest quality requirements with extreme cost efficiency. The Piccol aser is constructed very compact:The four integrated motorized axes allow a repeat accuracy of 0.1 mm. An accurate control system handles movement in the x, y and z axes as well as the rotational axis. Thanks to its modular design, the system can be matched exactly to the particular technical requirements preferred.

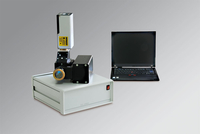

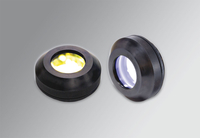

Pinpoint accuracy

The Piccolaser replaces the conventional methods of soldering, welding and fusing, but is far quicker, more precise and has repeat accuracy: Set parameters can be easily called up again at any time. In contrast to normal soldering or conventional gas welding, a homogeneous melt is produced at the fusion point of the materials to be joined.

Accurate point or area laser welding, therefore, delivers an optimum result without discolouration, spots or beads. This makes physical or optical quality defects and costly reprocessing a thing of the past, saving time and money. Laser instant adjustments can be carried out immediately.

Perfectly suited for Jewelers and Goldsmiths

The Piccolaser was not only developed for laser experts but also for technicians intending to simply bond metal to metal. The use of this laser system is quick and easy to learn and you will have the support of our MT Laser Team. The handiness and mobility of the Piccolaser makes any job that calls for detail and artistry, quicker, easier and programmable to ensure consistency. The results exceed conventional processes for all welding and joining tasks.

Time savings of up to 70%

For combining casted parts made of dental alloys a „second“ or „third“ alloy with a low melting point is needed. The melting point or melting range of the solder has to be lower than the solidus point of the alloys to be soldered. Otherwise the parts to be combined would be deformed and melt during the soldering.

The PICCOLASER system offers accurate influence of precise energy packets.

By limiting the welding zone it is possible to work directly on the master model. Furthermore does the trend towards laser-instant-corrections offer new opportunities for your business.