Laser plastic welding

Today, laser plastic-welding is replacing other joining techniques such as gluing and ultrasonic welding in many manufacturing and industrial fields. The modern joining process for plastics is highly flexible and free of particles and solvents, and it provides high-strength connections without marking or damaging the work surface. Plastic laser-welding is invaluable when precise control and accuracy is needed to protect vital internal components, and it can be used to successfully weld plastics even when faced with challenging geometries.

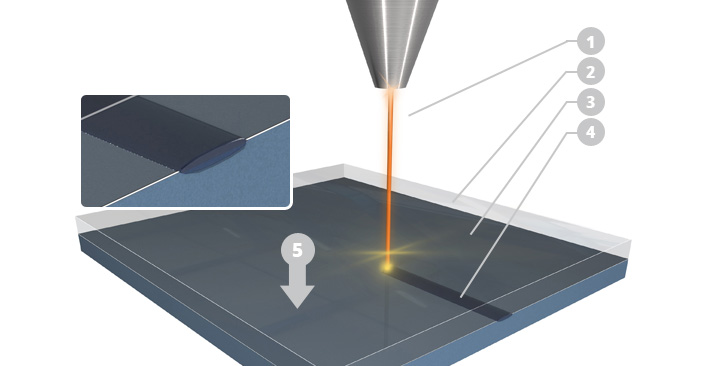

With this illustration, you can see the process of laser plastic welding at work

1: Laser beam 2: Transparent plastic 3: Absorbed plastic 4: Diffusion zone 5: Joining pressure

Laser-welding plastics utilizing the laser transmission welding method joins two thermoplastic plastics, a transparent plastic and an absorbing joining partner. The laser beam penetrates the upper, laser-transparent component and melts the lower, laser-absorbing component, which then bonds with the transparent plastic. When done properly, this creates a leak-free, secure weld.

With this type of overlapping welding, the weld is generated on the inside of the component without the release of particles. It creates a nearly invisible, optically high-quality weld with opaque components. The local heat input with the laser has a minimal impact on the components, so welds can be created even in the immediate vicinity of electronic components. Because laser plastic-welding creates a weld without the need for solvents, it reduces industrial waste and saves on cost, making it a green solution for manufacturers.

There are four main techniques used in laser plastic-welding

- Contour welding: Used for welding three-dimensional or large parts, contour welding moves the laser in a single pass along the welding joint.

- Mask welding: Laser-welding plastic with this method utilizes a wide beam that moves over the entire surface being welded, with a shield protecting areas where welding is not desired.

- Quasi-simultaneous welding: This technique utilizes a small beam that makes several passes over the welding joint.

- Simultaneous welding: Multiple beams pass simultaneously over the welding joint.

For more than 20 years, MT Laser has been at the vanguard of laser technology and innovation. Our plastic-welding services and equipment are industry-tested, perfect for any professional need, and among the best available for sale today.

Browse our selection of laser plastic-welding equipment, or contact us to receive information customized for your welding needs.