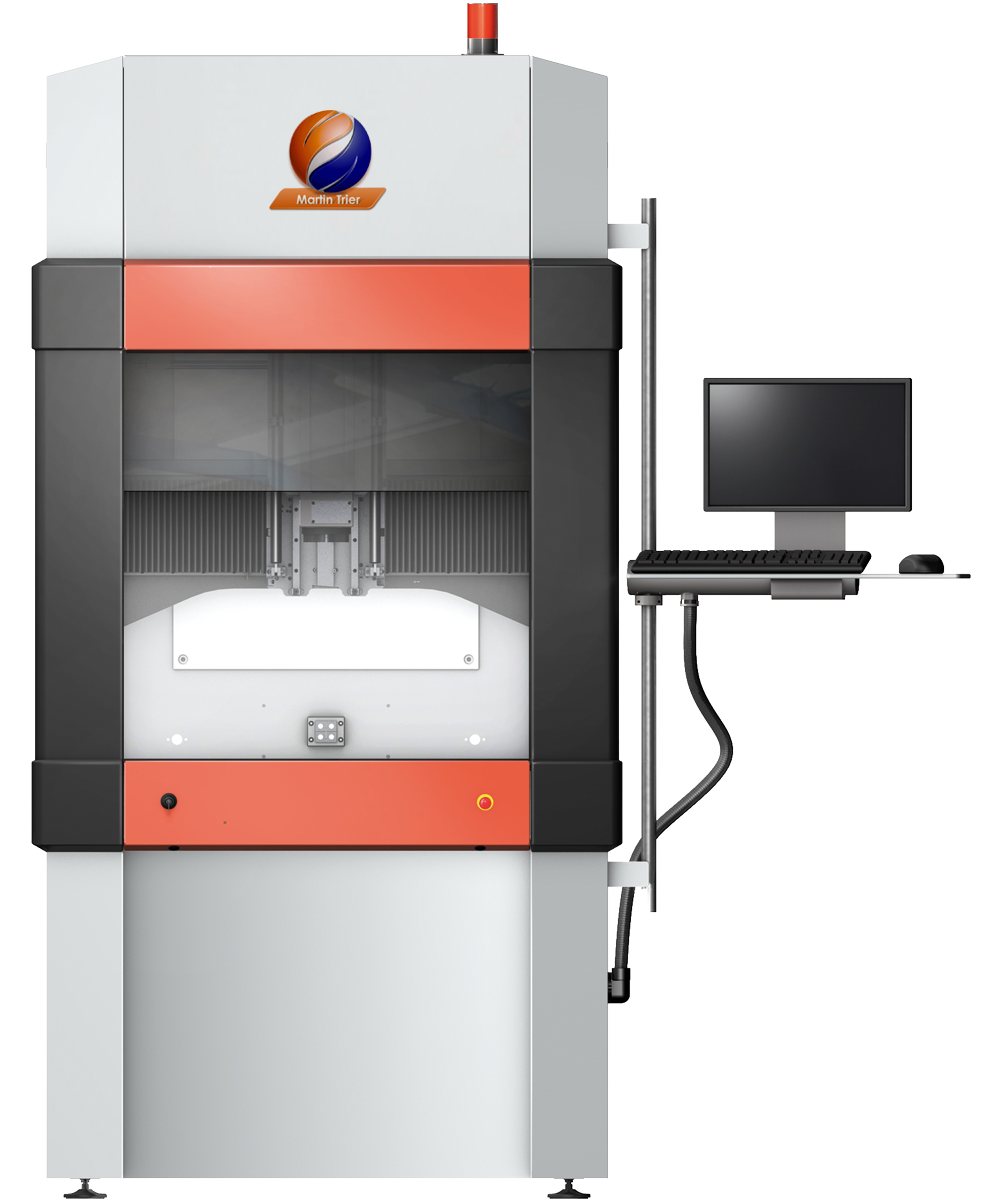

MTLAS PORTAL

The new dimension in laser marking

Marking, engraving and lettering with linear actuator for five axes

Highlights at a glance

-

Pulsed fiber laser with excellent beam quality (M² <1.3)

(Optionally available as a short-pulse laser) - Maximum precision by synchronously moving all axes

- User-friendly setup with 3D joystick

- With the labelling software, all characters, objects, graphics, logos, bar codes, data matrix codes can be displayed.

- All steel materials, nonferrous metals can be labelled. Ceramics and glass (pre-processing with special laser marking spray).

- High marking quality: Abrasion-resistant, weather-resistant and environmentally friendly

- Non-contact and low-distortion processing

- Maximum lettering field size 700 mm x 700 mm

- Processing of work pieces with a weight of up to 1000 kg

- Positioning and repetitive accuracy of the linear axes: 0.01 mm

- Maximum acceleration of the linear axes 1 m/s²

- Maximum travel speed 30 m/min

- Compatible with CAD / CAM software solution MTLAS SUITE

- Compatible with the powder feeder and powder nozzle

For high loads. With best results.

With innovative marking lasers, MT Laser has ever since set standards with regard to marking, engraving and lettering. The MTLAS PORTAL even tops it. The system impresses with a strong laser power of 50 W with highest precision. It is the ultimate solution for all imaginable marking and engraving tasks. The minimal spot width is 50 μm in a focused status at a pulse energy of max. 1.5 mJ.

The highly dynamic and precise laser processing station is equipped with a linear actuator for three axes. Each axis reaches an acceleration of 1 m/s2 at maximum speeds of 30 m/min. The solid granite construction along with a portal construction and direct position sensor system provide a maximum of precision.

All very simple. All under control.

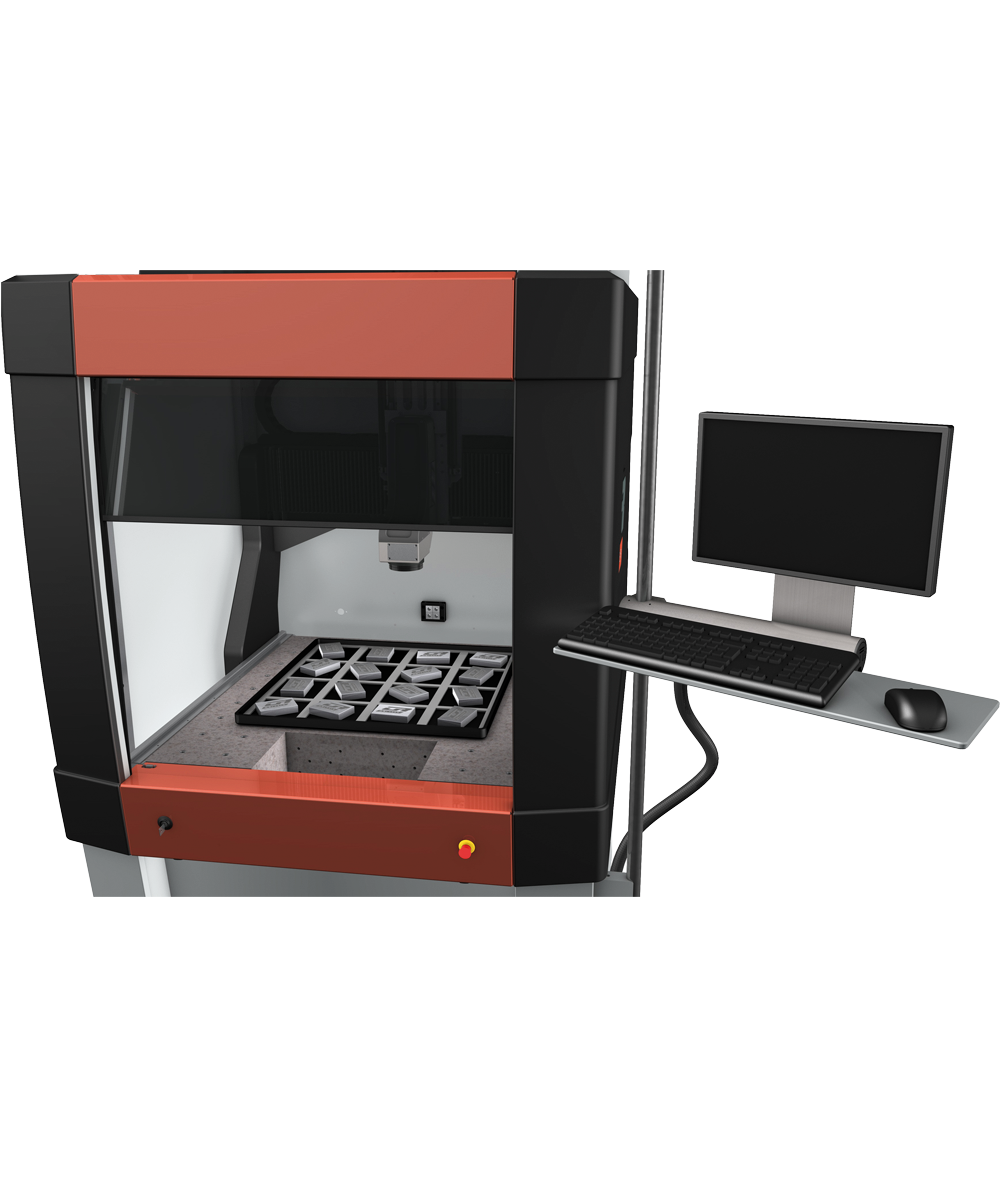

Through a camera-based adjustment function, the setup effort can be reduced to a minimum in the run-up to the material processing. Thanks to the high-resolution camera system, a component positioning with highest precision and low effort is implemented. The user has the possibility to create layouts for lettering on the work piece shown in real time as well as to watch the following work process live.

A key feature of the software package is the automatic component recognition. Unpalletized and loosely introduced work pieces into the marking machine are recognized in their position by the software. Subsequently, the lettering will automatically be applied at the right place.

1,000 kg are no problem at all for the MTLAS PORTAL.

The system is able to process and edit big or palletized work pieces with a weight of up to 1,000 kg in its generous space of 800 mm x 800 mm x 200 mm. This is made possible by a high-tech scanning head and three highly precise dynamic axes driven by linear engines. The axes reach a maximum acceleration of 1 m/s² at a maximum travel speed of 30 m/min. The work bench consists of a thick granite plate. This ensures a completely vibration-free and highly precise processing at very high speeds.

The maximum flexibility of the system is further complemented by an axis of rotation and a rotary table that can be used optionally. As with all closed laser systems of OR Laser, the system meets the highest safety standards and can be used in all rooms without further safety precautions.

Works seamlessly: in-house hardware and software

The system is controlled via a marking and engraving software developed by MT Laser. The software with a big functionality fulfils several requirements for a modern industrial factory. It is ideal for surface finishing, post-processing of CAD files, list entries for marking sequences, external trigger control, direct entry of texts, barcodes, data matrix code, time and date, linear, radial and polylinear texts. Importing of AI, DXF, HPGL, BMP and JPG files, for example, is easily possible.

The entire editing process can be followed in real time using a high resolution camera. In addition, the integrated automatic component recognition improves the "marking on the fly" functionality as well as many other useful features and thus allows for an efficient and economic product use.

Optional: Operating via MTLAS SUITE

The MTLAS SUITE from OR Laser is an unprecedented new CAD/CAM environment for planning nearly all facets of laser processing: marking, engraving, cutting, welding, cladding, and powder-based additive manufacturing processes.

This is the first and only comprehensive software for industrial laser applications that is actually able to read and process all proprietary file formats and control all existing laser systems.

The MTLAS SUITE is excellently suited for supporting and planning processing strategies. The software supports the most popular 3D CAD file formats including STEP and IGES. The system also doubles as a tool for classic welding and marking tasks as well as powder-based laser cladding (also for depositing multiple layers).

Specifications

Workspace:

X axis 600 mm

Y axis 600 mm

Z axis 380 mm

Feed:

Quick movement X/Y/Z 30/30/30 m/min

Working surface:

Mounting table 800 x 800 mm Max. component height 200 mm