Laser cladding with powder

Whether it is for repairs, wear-protection layers, or design changes, laser cladding with powder upgrades surfaces as if they were cast from one customized, industrial mold.

With laser cladding with powder, a filler metal powder coating is welded onto an existing component with a laser. A professional-looking layer, without pores or cracks and with little mixing and a small heat-affected zone, results.

This additive manufacturing process gives the components higher strength and increases the load capacity. Thanks to laser cladding with powder, repair instead of replacement becomes more cost-effective, as worn components can be renewed exactly at the stressed parts.

Laser cladding with a powder coating is not only a way to save money, but it is also an excellent way to save time that would otherwise be spent manufacturing replacements. The remaining material volume from this form of metal cladding shows no deformation and can keep its original properties. Through the use of metal cladding with lasers and a powder coating, components can be returned to operation quickly.

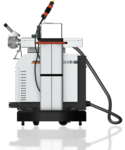

With this illustration, you can see the process of laser Cladding with Powder at work

1: Laser beam 2: Powder feed 3: Work piece 4: Application

Our laser systems for sale that are recommended for additive manufacturing

EVO MOBILE

The EVO MOBILE system is an excellent option for laser cladding with a powder coating in an open workstation. Some of the top features of the EVO MOBILE model include auto-weld, high-pulse peak power, an intern video function, and touch-screen technology. All of these features are packed into a compact size to eliminate the need to have a large workspace for laser cladding with powder.

LRS EVO

The LRS EVO model is another compact laser welding system. Like the EVO Mobile model, it is ideal for an open welding workstation. Features of the LRS EVO include two Z axes, a teach-in function, simple operation, range ability, motorized X/Y and Z travel, and a large table capacity of 350 kg.

LASERCAB

LASERCAB is a laser welding system that is designed for precision. With the system’s ability to change the diameter of the laser beam during welding, it offers a lot of flexibility. Other features include touch-screen technology, integrated fume extraction, auto-weld, X/Y and two Z axes, and a table load capacity of 250 kg. This system is recommended for busy production environments with heavy traffic.

ROBOLASER

The ROBOLASER model is packed full of possibilities for laser cladding processes. Along with cladding ability, this equipment also performs welding, cutting, and hardening. Other benefits include quick and short cycles, a large selection of filler materials, low thermal stress, high hardness, and no structural damage.