Laser welding processes

How does laser welding work?

All materials that can be welded conventionally can also generally be welded with laser welding processes. In regard to quality, speed, and economy, laser welding systems are superior to conventional processes for industrial projects, making laser welding equipment and services popular offerings for sale. Depending on the intensity of the laser radiation, laser welding is categorized as heat conduction welding or deep welding.

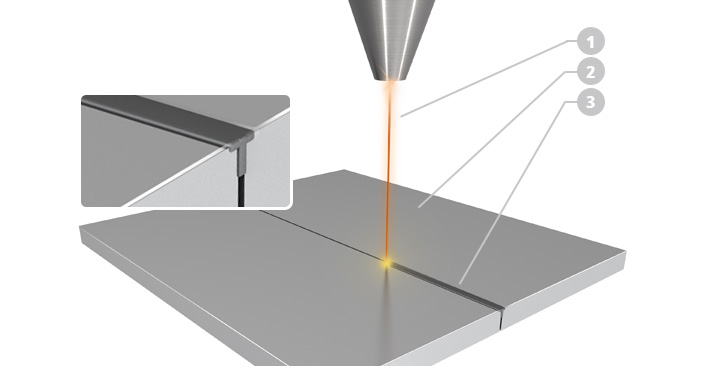

Heat Conduction Welding

With heat conduction welding, only the surface of the workpiece is melted using the equipment. In this laser welding process, the energy gets into the workpiece only through heat conduction. The welding depth for this process is generally lower than 2 mm. The laser beam melts the materials to be joined along the joint. The melts flow into each other, and the solidified melt connects the materials permanently. Heat conduction welding is used mostly to join parts with thin walls. The smooth, rounded weld does not need to be processed further once the laser beam welding process is complete.

With this illustration, you can see the process of laser welding at work

1: Laser beam 2: Workpiece 3: Weldseam

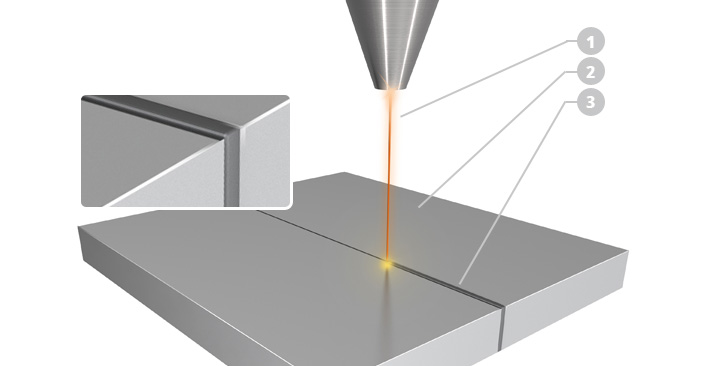

Deep welding

With deep welding, energy is also applied below the workpiece surface. It is used when a high welding depth is needed or when different material layers need to be welded at once.

With this illustration, you can see the process of deep laser welding at work

1: Laser beam 2: Workpiece 3: Weldseam

This process is characterized by high efficiency and high welding speeds, thanks to which the heat-affected zone is small and the deformation is slight. The intensity of the laser radiation is around 1 MW per square centimeter. During this process, the laser beam melts the material and also creates a deep steam capillary (also called keyhole) with approximately 1.5 times the diameter of the laser beam. This steam capillary created by the laser welding process is surrounded by the melt.

The steam capillary moves through the workpiece together with the movement of the laser beam over the joint. A small, deep weld is formed as the melt flows around the steam capillary and solidifies at the rear. The laser beam is guided deep into the material by total reflection into the steam capillary, so that welding depths of up to 25 mm can be realized for steel. The weld depth may be 10 times larger than the weld width when this laser beam welding process is complete.

Each of these welding processes have multiple practical uses within the manufacturing industry. In the hands of the right professional, the technology can help create customized pieces for various applications.