Scanner welding

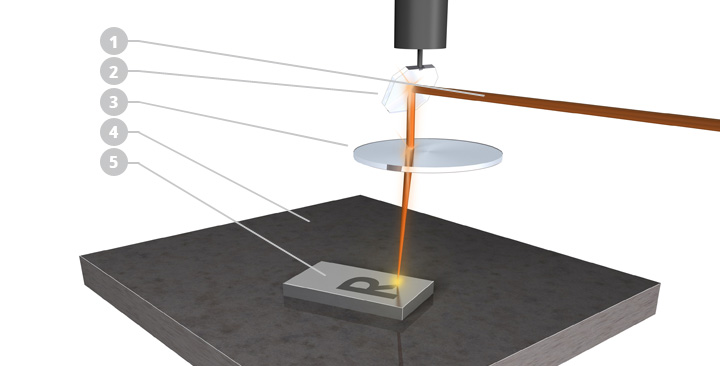

The following applies to welding in batch production: Time is money! Scanner welding initially saves much time, as the movement of processing heads or workpieces is eliminated with this technology. Instead, the laser beam is guided via movable rotating mirrors. The laser beam is deflected, positioned, and focused via the rotating mirrors. Quick and precise welding can be done in the resulting processing field. When doing so, the size of the processing field depends on the deflection angle and the working distance. The possible focus diameter at the workpiece and the processing speed depend on the focal length of the optics used, the material, and the beam properties of the laser.

1: Laser beam 2: Scanner 3: Objective 4: Working field 5: Work piece

The following applies to welding in batch production: Time is money! Scanner welding initially saves much time, as the movement of processing heads or workpieces is eliminated with this technology. Instead, the laser beam is guided via movable rotating mirrors. The laser beam is deflected, positioned, and focused via the rotating mirrors. Quick and precise welding can be done in the resulting processing field. When doing so, the size of the processing field depends on the deflection angle and the working distance. The possible focus diameter at the workpiece and the processing speed depend on the focal length of the optics used, the material, and the beam properties of the laser.