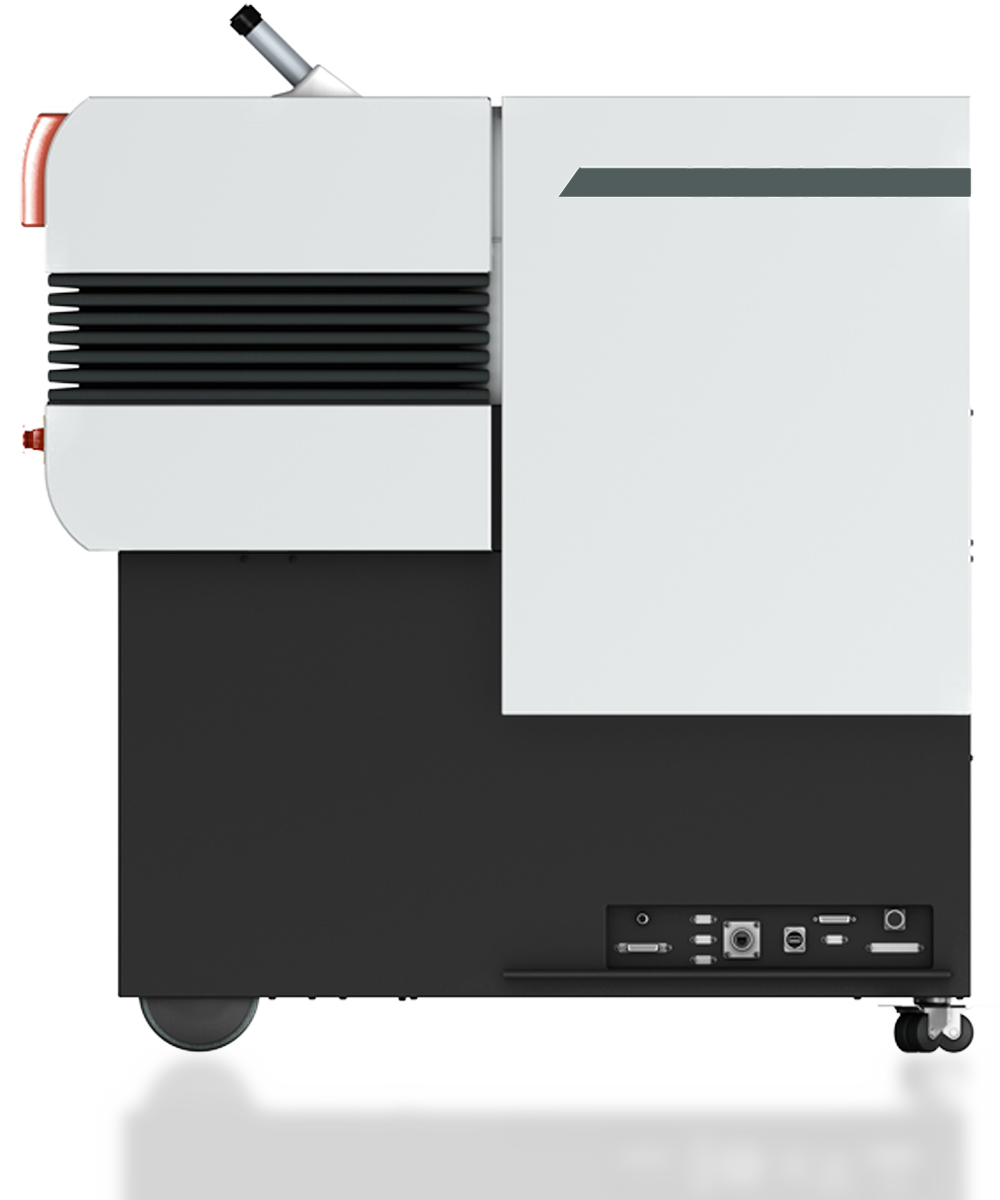

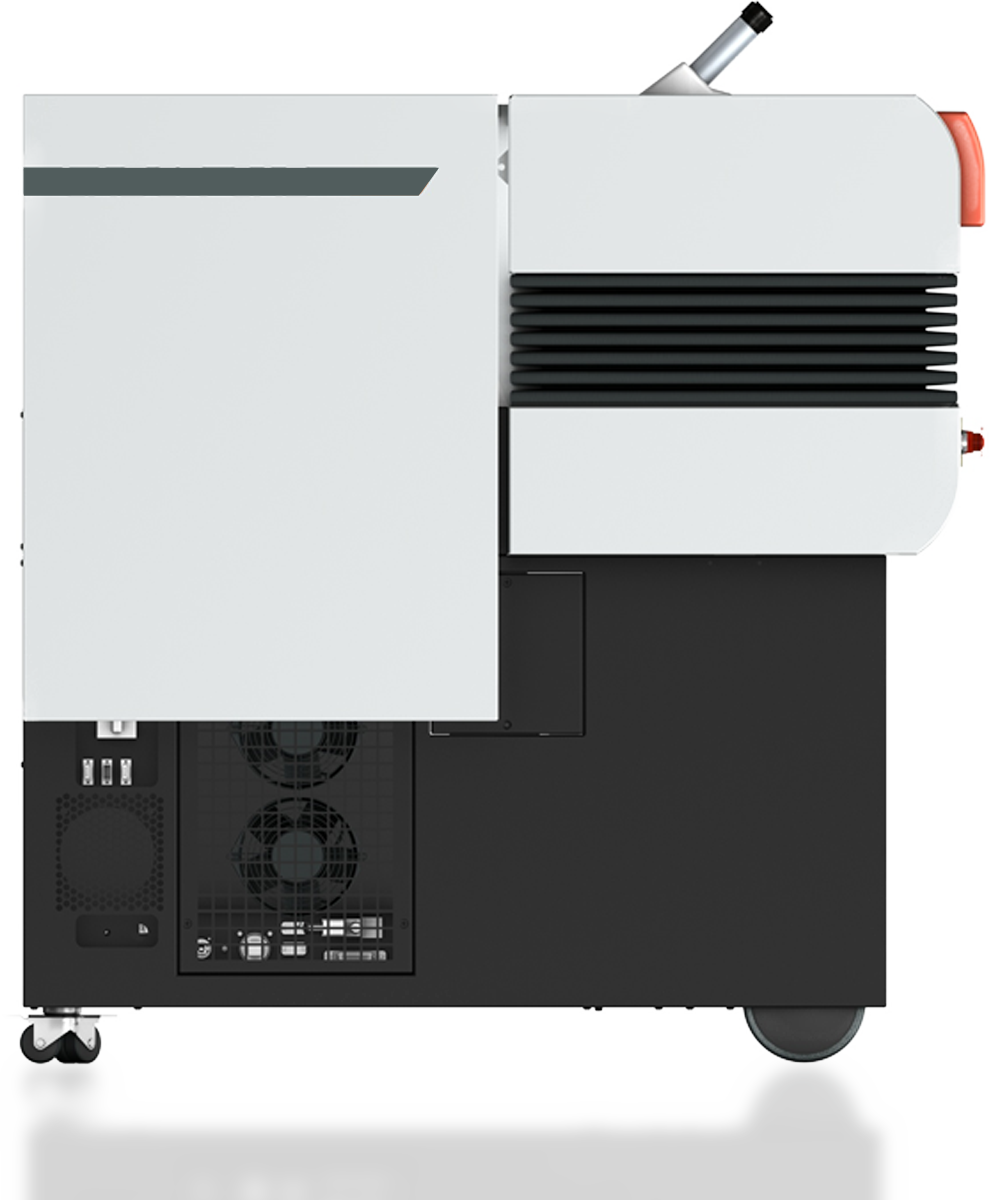

LASERCAB

The universal laser solution

Highlights

- x/y and two z axes

- Touch display for parameter settings

- The table’s z axis has a load capacity of up to 250 kg

- Up to 5 axes control

- Crane loading possible

- Integrated fume extraction

- Autoweld for automated laser welding tasks

- Compatible with CAD / CAM software solution MTLAS SUITE

- Compatible with the powder feeder and powder nozzle

The Class 1 laser for industrial and highly frequented production environments

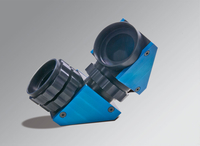

The Laser machining station LASERCAB is designed to process precision parts by laser welding and laser cladding. Via a variable beam expander it is possible to change the laserbeam diameter during the process of the system.

Whether you are processing the common alloys in tool- and mold making or even aluminum, copper or titanium, the performance of the LASERCAB is especially designed for these processes.

Intuitive Bedienung via Touch - Screen

The operation of the LASERCAB can be done over a touchscreen display which has access to all parameters and saved data. All important functions are accessable with just a few clicks. Additionally preset data can be saved anytime and will always be retrievable for further welding operations.

The display surface of the LILLY-BOARD is divided into three screens and enables a quick navigation within the software. In the status window all system relevant information are displayed. The parameter window shows all current system parameters or welding parameters and enables changes of these values during the welding operation by the user.

The welding outline is precisely created in the control software which has a wide fuctional range of DXF-Files which can be loaded into the program. With a pilot laser the welding operation can be displayed directly onto the workpiece.

Optional: Operating via MTLAS SUITE

The MTLAS SUITE from MT Laser is an unprecedented new CAD/CAM environment for planning nearly all facets of laser processing: marking, engraving, cutting, welding, cladding, and powder-based additive manufacturing processes.

This is the first and only comprehensive software for industrial laser applications that is actually able to read and process all proprietary file formats and control all existing laser systems.

The MTLAS SUITE is excellently suited for supporting and planning processing strategies. The software supports the most popular 3D CAD file formats including STEP and IGES. The system also doubles as a tool for classic welding and marking tasks as well as powder-based laser cladding (also for depositing multiple layers).

Safe and ergonomic

The LASER CAB system is a class 1 laser, whose enclosed construction allows laser-welding work to be undertaken safely, even in non specially designed areas. It also allows larger components to be positioned into the unit using a crane, because the cabinet opens upwards. Whether you want to apply the metallurgical alloys typically used in tool and mold making or also use aluminum, copper or titanium, the laser power of the LASER CAB series is best suited to do the job. The easy to open flap of the LASER CAB system’s safety covers and the use of a swivel crane allow you to position heavy components.

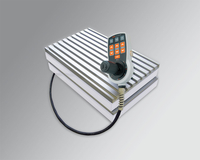

Components of this Lasersystem

1 cooling System | 2 motorized x - y table | 3 wire feeder (optional) | 4 machining head with beam expansion | 5 resonator | 6 lilly Controller | 7 joystick | 8 supply unit