Laser cladding

Laser cladding is an excellent option if you want to repair or modify older equipment. This may be a more affordable option than looking for similar equipment for sale.

At MT Laser, we can help with industrial projects so that you can continue to operate on your schedule. We have service centers in four different countries and more than 30 partners worldwide, and whether you need repairs or to purchase your own laser cladding equipment, we can help.

Laser cladding with powder and wire for repair and modification

With laser cladding, surface application is performed by melting of a material on a workpiece. Laser cladding is used for the upgrading of surfaces and to repair or modify components that cannot be replaced cost-effectively. Manual or automated processing is possible.

It is the high quality of our laser cladding services that provides the primary advantage of this process over other repair processes. We can customize the repair to solve the problem and help your equipment to continue to work.

Heat-sensitive surfaces and coatings are treated in a relatively distortion-free manner. Even the typical discoloration on polished surfaces and branding spots fails to materialize. Adjacent grains remain unchanged. The otherwise extensive post-processing is reduced to a minimum. Our customized services mean that you will get the exact repair that you need.

Application video for laser cladding with powder

Fully automated application

Laser cladding with powder melts the metal powder onto the material and connects it to the metal of the workpiece. In industrial use, laser cladding with powder is used mainly with full automation. Laser cladding with wire or strip as a filler metal functions similar to the process with powder and is used mainly in manual laser welding installations.

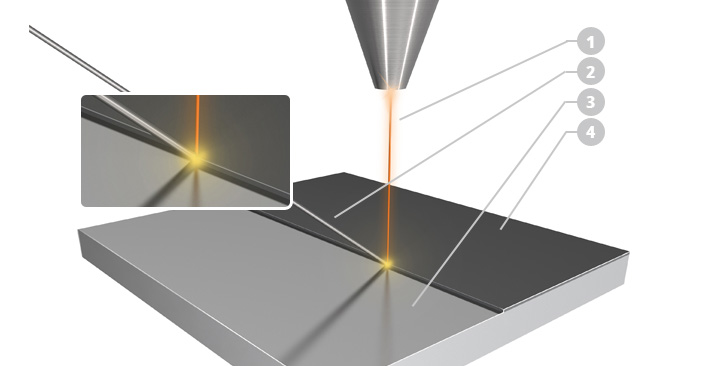

With this illustration, you can see the process of laser cladding with wire at work

1: Laser beam 2: Wire 3: Work piece 4: Application

At MT Laser, we can help you keep your systems running. Our technology and professional laser cladding equipment will surely help you meet your needs. We have worked on perfecting our tools to ensure that our customers can keep their manufacturing processes running with a minimum of interruption.

Contact us today to learn how our laser cladding services can help your company.