POPULAR PRODUCTS

LASER SYSTEMS OF OR LASER AT A GLANCE

- Laser Products / Types OF Laser Usehttp://www.martintrier.com/en/laser-cutting/http://www.martintrier.com/en/laser-marking/http://www.martintrier.com/en/laser-hardening/http://www.martintrier.com/en/laser-remelting/http://www.martintrier.com/en/laser-drilling/

Laser welding

Laser welding is well established in the industry as a high-quality, efficient, and economic process for joining of plates, plastic components, jewelry, or even construction parts.

The essential processes are laser deep welding, heat conduction welding, and penetration welding for plastics.

Laser welding is used preferably for the joining of components with little allowable thermal load. The high welding speed with this welding process creates a very slender seam geometry with a large depth-width ratio. When the components to be joined are positioned with a minimum joint gap, the use of filler materials like wire can be waived for the welding process.

Practical experience has shown that a joint gap of max. 20 % of the laser spot diameter can be welded without problems.

If the components can initially be tacked by spot-welding and then are welded tight with a laser weld, elaborate devices are often not required for laser welding. This ensures that even small batch sizes can be processed cost-effectively by laser welding.

Depending on the intensity of the laser radiation, laser welding is essentially divided into the following processes.

Heat conduction welding

- The welding process is done via thermal conduction.

- Used for joining thin-walled components.

- The seam depth is only a few tenths of a millimeter to 1 mm.

- No rework of the weld required

Deep welding

- A high power density of approx. 1 MW per square centimeter is required.

- This is used for large welding depths or if several layers of materials are to be welded in a single step.

- The seam depth can be up to 25 mm.

Depending on the application, laser welding can be divided into

- Hybrid welding

- Plastic welding

- Spot and seam welding

- Pipe welding

- Scanner welding

BENEFITS OF LASER WELDING COMPARED TO CONVENTIONAL LASER PROCESSES

- Different material types and thicknesses can be welded.

- Results with high quality

- High automation and welding speed

- Min. thermal material impact, little or no load

- Very slender seam geometry with large depth-width ratio

- Point-accurate, precise energy input

- Contact-free, force-free processing

- Welding of complicated weld geometries

- Min. spatter

- Shorter time required for rework

LASER SYSTEMS RECOMMENDED FOR THESE APPLICATIONS

- ECO LASER

- HTS MOBILE

- EVO MOBILE

- LRS EVO

- LASER CAB

- ROBOLASER

- PICCO LASER

- IQ LASER

Laser deposition welding

Additive laser processing, wear protection, and repair processes are nowadays essential and are used mostly when expensive, large components cannot be replacer cost-efficiently, for example

- Plastic injection molds

- Aluminum die casting

- Punching and cutting tools

- Drop forging

- Engine parts

- Turbine parts

Laser deposition welding or laser coating uses a laser to deposit material on a base material, where the hardness and the properties of the deposited material correspond exactly to the original state of the component. Here, use of a laser allows very precise work in comparison to conventional deposition welding with minimal heat input and maximal absence of load.

Depending on the material to be deposited, the welding processes are categorised as follows.

Laser deposition welding with wire

Laser deposition welding with filler wire is used widely in the industry and can be done manually or automatically. Whether it is correction of production faults, design changes, or repair of defects: The laser beam welds the filler wire with point accuracy to the workpiece and permits area deposition. With a wire diameter of 0.1 to 0.8 mm as a rule, deposition can be performed manually or automatically by CNC and wire feeder. In special cases, filler wire with a thickness of 1.0 mm and 1.2 mm can also be used. However, this is rather an exception.

The filler wire is melted completely, while the base material is melted for 0.3 to 0.5 mm and combines solidly with the added material. The small dilution results in a very small heat-affected zone of a few tenths of a millimeter.

Deposition welding with powder

In the case of laser deposition welding with powder, the powder is fed automatically to the processing point, it is applied in layers, and it is melted to the base material without any cracks. The traces here are applied with CNC control, allowing high reproducibility and making it possible to deposit even larger quantities quickly. The new material layer created in this way can be processed further after cooling. A multitude of powder types is available for powder deposition welding. Material combinations or alloys serve for building-up or repair, creation of plating, wear protection layers, or corrosion protection, and they can be adapted to the mechanical and tribological requirements.

In the case of powder deposition welding, the coating strategy plays a special role, so that the systems are generally programmed offline and are then transferred to the CNC control. Powder application is performed by a co-axial or off-axis powder nozzle that is combined with the laser optics in a laser processing head. Lasers with a few hundred Watt up to several kW are used, allowing deposition rated up to 10000 mm3/h.

Laser deposition welding with powder is used especially in sectors like toolmaking and mold building, in aviation and astronautics, or automobile manufacture, and it is used for

- Changing of surface geometries

- Creation of new surface properties

- Wear protection

- Production of functional layers

LASER SYSTEMS RECOMMENDED FOR LASER DEPOSITION WELDING

- ECO LASER

- HTS MOBILE

- EVO MOBILE

- LRS EVO

- LASER CAB

- ROBOLASER

- PICCO LASER

- IQ LASER

- IQ LASER

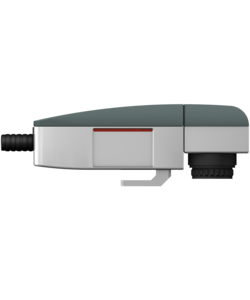

IQ LASER

This Lasersystem is highly suitable for: Laser welding Laser deposition welding Laser cleaning

The diode-pumped IQ manual welding laser system has been designed for applications in the sectors of laser deposition welding and joining. Here, the IQ convinces especially by its intuitive handling via a touchscreen and the good quality of the welding and joining results. Compact and flexible, extremely powerful, suited for mobile use, and highly efficient: By intelligent use of leading-edge technology, the IQ manual welding laser permits reduction of downtimes in the production process.

BENEFITS AT A GLANCE

- Diode-pumped manual welding laser

- Laser power from 150 W to 300 W

- A simple receptacle is sufficient!

- Excellent beam quality

- Motion sensor

- Built-in camera

- Operation via touchscreen

- High processing speed

You can find further information concerning the specifications, the application fields, and the accessories of the IQ LASER on the detailed product page.

- ECO LASER

ECO LASER

This Lasersystem is highly suitable for: Laser welding Laser deposition welding

The ECO LASER system is the answer to the search for a cost-effective laser welding solution for mini-series or individual parts. The ECO LASER is thus the first choice of small and start-up enterprises for laser welding and laser deposition welding. The ECO LASER represents a suitable solution for experts or larger companies that want to expand their welding capacities.

BENEFITS AT A GLANCE

- Open laser welding system for individual requirements

- Small, compact, precise, and quickly ready

- Intuitive 5’’ touchscreen display

- Joystick serves as central operating unit

- Practical-based operation

- Motorized travel in X/Y/Z and R/axis

- Teach-in function

- Autofocus system (optional)

You can find further information concerning the specifications, the application fields and the accessories of the ECO LASER on the detailed product page.

- EVO MOBILE

EVO MOBILE

This Lasersystem is highly suitable for: Laser welding Laser deposition welding

The EVO MOBILE laser system is quickly ready for operation and extremely precise. In addition to high, practical-based operational comfort, it offers CNC processing functions for laser welding and laser deposition welding and thus meets the increasing demands of mobile service providers or in tool and mold building, but also other sectors like aeronautics, mechanical engineering, or sensor manufacture can profit from the outstanding properties of EVO MOBILE.

BENEFITS AT A GLANCE

- Open, compact, mobile, and flexible laser welding system

- No lamp change required

- Electromagnetically controlled swivel arm, revolving around its own axis

- Operation via touch screen

- One-hand operation of all functionalities via joystick

- Auto-weld function

- Internal video function

- Welding made easy thanks to coordinate transformation

LASER SOURCES

The EVO MOBILE laser system can be equipped with the following laser sources:

- Lamp-pumped Nd:YAG laser

- Diode-pumped Laser

You can find further information concerning the specifications, the application fields, and the accessories of the EVO MOBILE on the detailed product page.

- HTS MOBILE

HTS MOBILE

This Lasersystem is highly suitable for: Laser welding Laser deposition welding

Constructive use for laser welding and laser deposition welding: The HTS MOBILE laser system proves itself extremely strong, robust, and adaptable in practice, and it combines flexibility with stability in repair of small precision parts, for example for the aeronautical industry, as well as for large injection molds used for example in the manufacture of bumpers.

BENEFITS AT A GLANCE

- Open, robust, adaptable laser welding system with swivel arm

- Laser power from 120 W to 300 W

- Motorized travel in X/Y/Z and R-axis

- Teach-in function

- Digital joystick

- Vibration arm by high-quality rail systems

SPECIAL EQUIPMENT

The laser autofocus system serves for fully automatic distance control and focusing of any welding surface and facilitates processing of 3D surfaces.

- Speedier and more precise work with a productivity increase of up to 50 %

- Consistent laser parameters at the workpiece

- Automatic on-line focusing

- Measuring accuracy of 50 µm

You can find further information concerning the specifications, the application fields, and the accessories of the HTS MOBILE on the detailed product page.

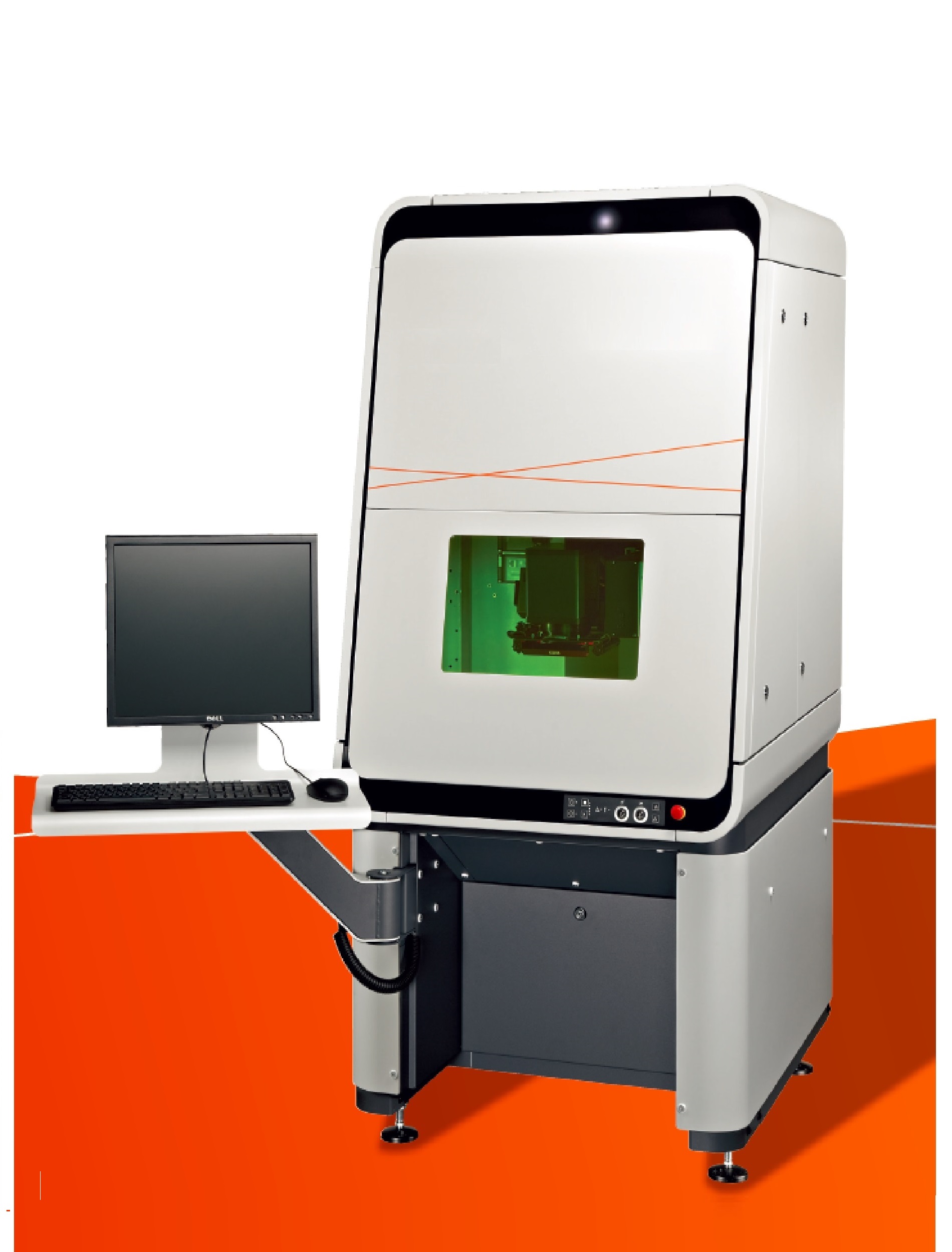

- LASERCAB

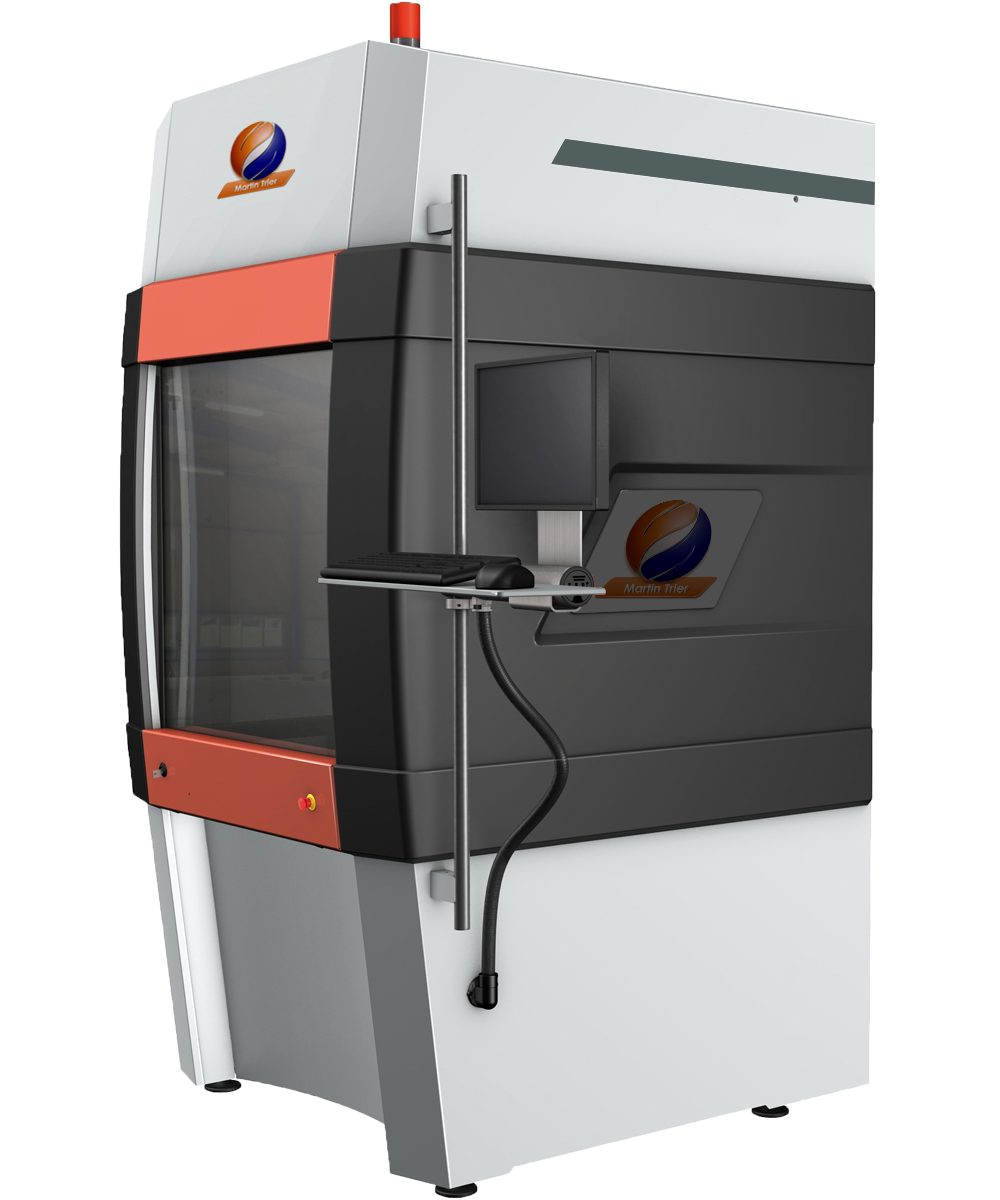

LASERCAB

This Lasersystem is highly suitable for: Laser welding Laser deposition welding Laser cutting

The specific focus of the LASER CAB is on laser welding and laser deposition welding. Here, because of its closed design, the class 1 laser also allows safe laser welding work in other than special areas and offers the ability to pick up even larger components in the processing area with the aid of a crane.

In addition to the range of tasks for laser welding and laser deposition welding, the LASER CAB offers laser cutting of metals with good quality.BENEFITS AT A GLANCE

- Enclosed class 1 laser system

- X/Y and two Z-axes

- Touch display for parameter adjustment

- The Z-axis of the table can pick up loads up to 250 kg.

- Control of up to 5 axes

- Loading by crane possible

- Integrated smoke exhaust

- Auto-weld function for automated laser welding tasks in CNC operation

LASER SOURCES

The LASER CAB laser system can be equipped with the following laser sources:

- Lamp-pumped Nd:YAG laser

- Diode-pumped laser

You can find further information concerning the specifications, the application fields, and the accessories of the LASER CAB on the detailed product page.

- LRS EVO

LRS EVO

This Lasersystem is highly suitable for: Laser welding Laser deposition welding

The LRS EVO is a laser system satisfying the diverse requirements of tool and mold manufacture, machine building, or other fields where weld joints of high strength, precision, and free of deformation are required.

Intuitive in handling – quick and efficient in implementation. This system meet any requirement for processing of small to medium-sized molds. An extensive range of accessories, for simple as well as for complex laser welding tasks, expand the possibilities for laser welding and laser deposition welding.BENEFITS AT A GLANCE

- Intuitive and open laser system for small to medium-sized parts

- Automated processing by CNC processing

- Laser power from 120 W to 300 W

- Workpieces up to 350 kg are possible

- Large 10” touchscreen display

- Operation via touchscreen

- Two Z-axes

- Motorized travel in X/Y and R-axis

- Ergonomic design

SECTORS

The LRS EVO operates in nearly every sector:

- Automotive

- Mold building

- Aeronautics

- Machine building

- Medical technology

- Toolmaking

LASER SOURCES

The LRS EVO laser system can be equipped with the following laser sources:

- Lamp-pumped Nd:YAG laser

- Diode-pumped laser

You can find further information concerning the specifications, the application fields, and the accessories of the LRS EVO on the detailed product page.

- MAG BIG BOX

MAG BIG BOX

This Lasersystem is highly suitable for: Laser welding Laser deposition welding Laser cutting Laser marking Laser hardening Laser remelting Laser drilling Laser cleaning

The MAG BIG BOX laser system has been designed as a marking and engraving laser of the laser class 1 and is intended for laser lettering, marking, and engraving of heavy workpieces up to 115 kg. Here, the MAG BIG BOX convinces by its high flexibility and range of applications. The standard version has an integrated motorized Z-axis for travel of the laser unit and a powerful extractor system.

BENEFITS AT A GLANCE

- Enclosed lettering laser system

- Laser power from 10 W to 75 W

- CNC-controlled Z-axis for travel of the laser unit

- Motorized Z-axis with X-Y table (optional)

- Lettering field of 130 x 130 mm

- Lettering speed up to 5000 mm/sec

- Powerful exhaustion system

AREAS OF APPLICATION

- Metals

- Plastics

- Ceramics

- Glass

You can find further information concerning the specifications, the application fields, and the accessories of the MAG BIG BOX on the detailed product page.

- MAG BOX

MAG BOX

This Lasersystem is highly suitable for: Laser marking

The MAG BOX lettering laser is of interest to companies who increasingly process small components, for example individual parts or small series with a weight of up to 10 kg. No matter whether it is temper marking, foaming of plastics, laser engraving, laser removal, or 3D laser engraving: The MAG BOX provides results with high quality, and because of the enclosed housing with the laser class 1, it can be employed in all areas without any further safety measures.

BENEFITS AT A GLANCE

- Enclosed marking laser of the laser class 1

- Pulsed fiber laser of best beam quality

- Laser power from 10 W to 50 W

- Lettering field of 130 x 130 mm

- Processing table of 250 x 210 mm

- Motorized travel of the Z-axis - travel distance: 120 mm

- High lettering speed

- Fixture for an extractor system

AREAS OF APPLICATION

- Metals

- Plastics

- Ceramics

- Glass

You can find further information concerning the specifications, the application fields, and the accessories of the MAG BOX on the detailed product page.

- MAG COMPACT

MAG COMPACT

This Lasersystem is highly suitable for: Laser marking

The MAG COMPACT all-in-one lettering and engraving laser system is the cost-effective variant for application on the production line or for smaller components, and it allows high-speed lettering with a laser power of 10 W, built-in PC control, and software-supported variable focal length. Here, the MAG COMPACT convinces by its compact design, permitting quick and easy integration into any work environment.

The MAC COMPACT can be operated via PC, tablet, mobile terminal, or directly at the unit.BENEFITS AT A GLANCE

- Compact lettering laser

- Laser power of 10 W

- Operation possible via PC or tablet

- Software-supported variable focal length

- Min. size of the lettering field: 55 x 55 mm

- High lettering speed

AREAS OF APPLICATION

- Plastics

- Metals

- Ceramics

- Jewelry

- Electronic components

You can find further information concerning the specifications, the application fields, and the accessories of the MAG COMPACT on the detailed product page.

- MAG PRO

MAG PRO

This Lasersystem is highly suitable for: Laser cutting Laser marking

The MAG PRO laser is an OEM laser source that can be used as a stand-alone laser for marking, engraving, and cutting tasks in production lines or simply in the work area.

Because of its standardized interfaces and easy integration, the MAG PRO laser can be integrated easily into existing systems, for example as a replacement laser source, within the scope of a system upgrade or expansion of production installations for series production.

By use of different lenses and interface extensions, the MAG PRO laser can also be converted quickly for any application.

BENEFITS AT A GLANCE

- Easy integration

- Pulsed fiber laser of best beam quality

- Laser power from 10 W to 50 W

- High lettering speed

- Marking on the fly

AREAS OF APPLICATION

The MAG PRO can be used ideally for the following applications:

- Annealing lettering

- Foaming of plastics

- Laser engraving

- Laser removal

- 3D laser engraving

- Cutting tasks

You can find further information concerning the specifications, the application fields, and the accessories of the MAG PRO on the detailed product page.

- LAS PORTAL

LAS PORTAL

This Lasersystem is highly suitable for: Laser welding Laser cutting Laser marking

The MTLAS PORTAL processing system combines precision with high processing speed and reliability. Lettering, engraving, marking, laser cutting, or welding: The MTLAS PORTAL offers a wide scope of functions while at the same time offering intuitive operation through the marking and engraving software MTLAS SUITE developed especially for it.

BENEFITS AT A GLANCE

- Complete system as a portal construction with linear drives and scanner

- Laser power from 30 W to several kW

- Equipment for up 5 axles possible

- Max. precision by synchronized movement of all axes

- Minimizing of the setup efforts by a camera-supported adjustment function

- Suitable for workpieces up to 1,000 kg

- High processing speed

Areas of application

- Metals

- plastics

- ceramics

- glass

- foils

You can find further information concerning the specifications, the application fields, and the accessories of the ORLAS PORTAL on the detailed product page.

- LASSTATION

LASSTATION

This Lasersystem is highly suitable for: Laser welding

The diode pumped MTLAS STATION is designed for applications in the field of laser plastic welding and can be used for the production of small series as well as for mass production of large quantities.

The typical fields of use of the MTLAS STATION are: The automotive industry, medical technology, electronic industry or the consumer goods industry. Overall the MTLAS STATION distinguishes itself through its robustnes and flexibility as well as the possibility of easy integration of this system into diverse production enviroments.In the field of outline welding as well as simultaneous welding the results are of high quality

Highlights at a Glance

- Scanner Technology

- Outline and simultaneous welding

- 24/7 operational

- low heat influence no pre treatment and aftercare is necessary

- Online Process control

- variable spot diameter

- low cycle times

- high productivity

- precise welding seams

You can find further information concerning the specifications, the application fields and the accessories of the ORLAS STATION on the detailed product page.

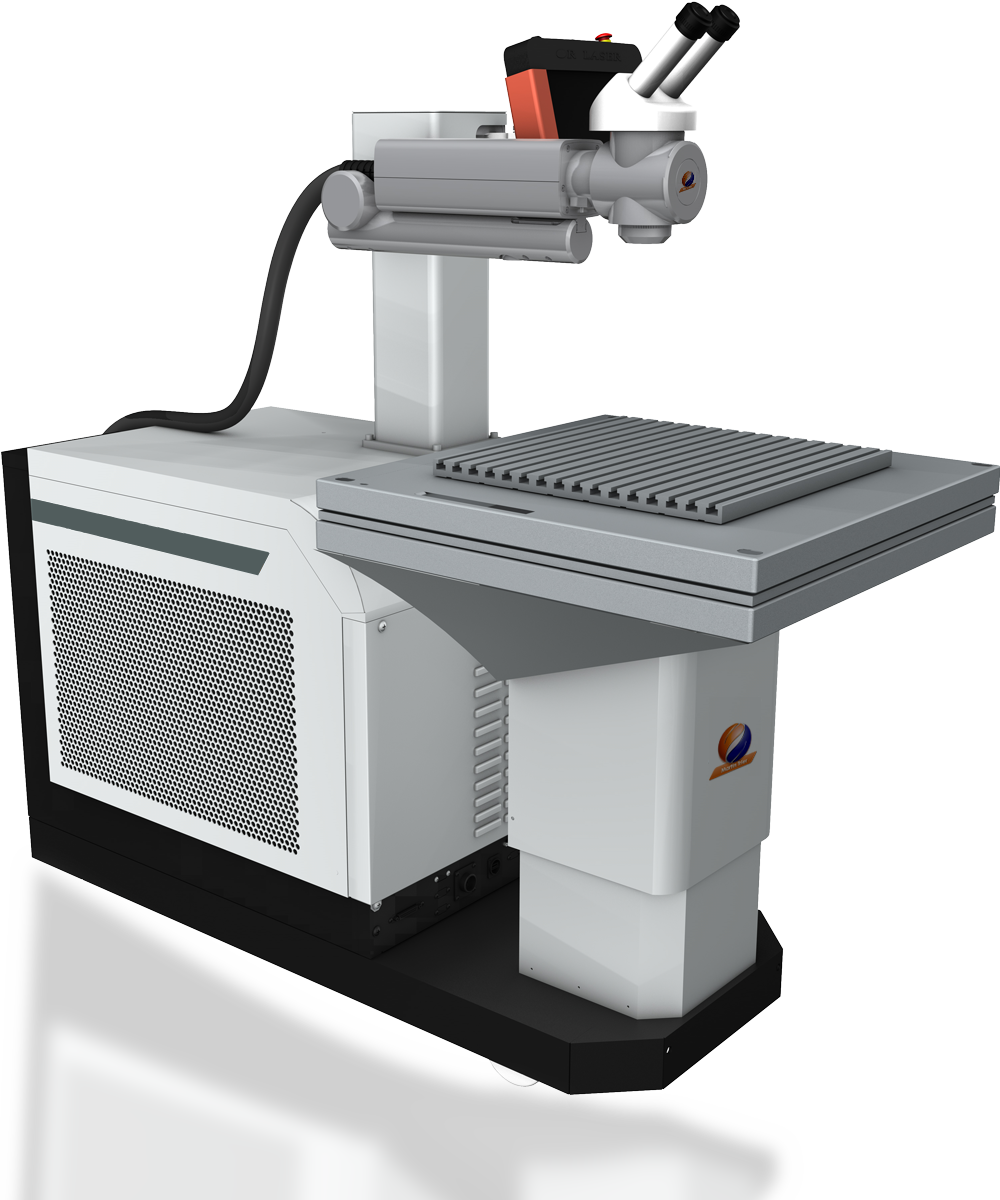

- PICCOLASER

PICCOLASER

This Lasersystem is highly suitable for: Laser welding Laser deposition welding

The PICCO LASER was developed for dental technicians, goldsmiths, and for the production of sensitive components like sensors or miniature components. Whether it is laser welding or laser deposition welding, the PICCO LASER offers a variety of applications and an intuitive, easily learned user interface and combines the highest quality requirements with the best possible cost-efficiency.

Delicate work is performed quickly because of its handiness and mobility, and the results surpass conventional processes by far.

A good beam quality and a high power from pulse to pulse permit welding of varied material combinations like gold, silver, titanium, brass, and copper, as well as high-quality stainless steel joints.

BENEFITS AT A GLANCE

- Compact, mobile, and flexible

- Program input and data display via touchscreen display

- All functions can be controlled via joystick

- Optional expansion to a motorized X/Y/Z-table

- A high-quality binocular allows precise work in the tenth-millimeter range

- Min. mechanical and thermal load for sensitive parts

- Time savings of up to 70 % with highest quality in comparison with conventional processes

You can find further information concerning the specifications, the application fields, and the accessories of the PICCO LASER on the detailed product page.

- ROBOLASER

ROBOLASER

This Lasersystem is highly suitable for: Laser welding Laser deposition welding Laser cutting Laser hardening Laser remelting Laser cleaning

The robot-controlled laser system ROBOLASER offers a total of six different processing types with a single laser system. Whether it is laser welding, laser deposition welding, laser cutting, laser hardening, laser remelting, or laser cleaning: Different processing heads that can be exchanged in a few minutes are available to the ROBOLASER for these applications, thus avoiding long retooling times.

With a laser power of a few 100 W up to several kW, the ROBOLASER can be adapted individually to any application and any budget.

Here, the applications can be programmed easily offline on the computer. Various laser applications filed in the software are available as strategies that can be applied to the components and can be adapted when required. Required information like 2D or 3D data can be integrated into the system via interfaces.

BENEFITS AT A GLANCE

- Versatile and flexible integration possibilities in the production process

- Laser strategies are on file in the software and are programmed offline

- Laser power from 300 W to 10 kW

- Precise and uniform parts quality

- Protection class IP67 for rough use conditions

- Large selection of filler materials

- Welding of similar materials is possible

AREAS OF APPLICATION

- Toolmaking and mold building

- Punching dies

- Housing components

- Machine building

- Food processing

SPECIAL EQUIPMENT

- Laser robots

- 6 axes industrial robot and expansion axes, tilt rotation axis

- Special processing heads and optics

- Powder nozzles and inert gas nozzles for laser welding and laser deposition welding

You can find further information concerning the specifications, the application fields, and the accessories of the ROBOLASER on the detailed product page.

PROFESSIONAL LASER WELDING FOR INDUSTRIAL APPLICATIONS: THE CUSOMIZED LASER SYSTEMS OF MARTINTRIER LASER

In recent years, hardly any other invention has set newer and better standards in industrial material processing than laser technology. By now, applications using laser technology have established themselves in nearly all industry branches as the standard for high-value, efficient, and economical processes, and they have become indispensable for professional manufacturing processes. Industrial lasers have assumed their place as the professional tools of choice in many areas, and there is no sign that this will be coming to an end any time soon.

When it comes to the automotive industry, jewelry creation, electrotechnology, the plastics industry, the aviation industry, mechanical engineering, medical technology, tool and mold making, or dentistry, all of these sectors, as well as others, have one thing in common: They use the many advantages of laser welding and laser systems as a means of producing highly developed finishing techniques for precise work. Advancing laser technologies mean that we will be dependent upon these lasers for the foreseeable future.

Since 1968, Martintrier has acted determinedly to become one of the leading manufacturers of laser machines and professional laser equipment in Germany. Whether for regional enterprises or global players, manual or mobile lasers, marking lasers, or process-controlled CNC laser systems, Martintrier develops new laser technologies and laser systems perfectly tailored to the applications of industry.

No matter whether you need laser welding, laser cladding, laser engraving, laser cutting, or laser marking, MT Laser offers you a wide spectrum of industrial laser systems with functions best tailored to your individual requirements. Our tools use the latest laser technology so that you know that you are always getting the best results from our equipment.

Our catalog of laser machines for sale has been designed to help our customers find exactly what they are looking for. In addition, we have a customer service staff that is well-versed in laser technologies and these laser machines and systems, and we can answer your questions and help you pick the best equipment for your manufacturing and other custom needs. Contact us today to learn more.