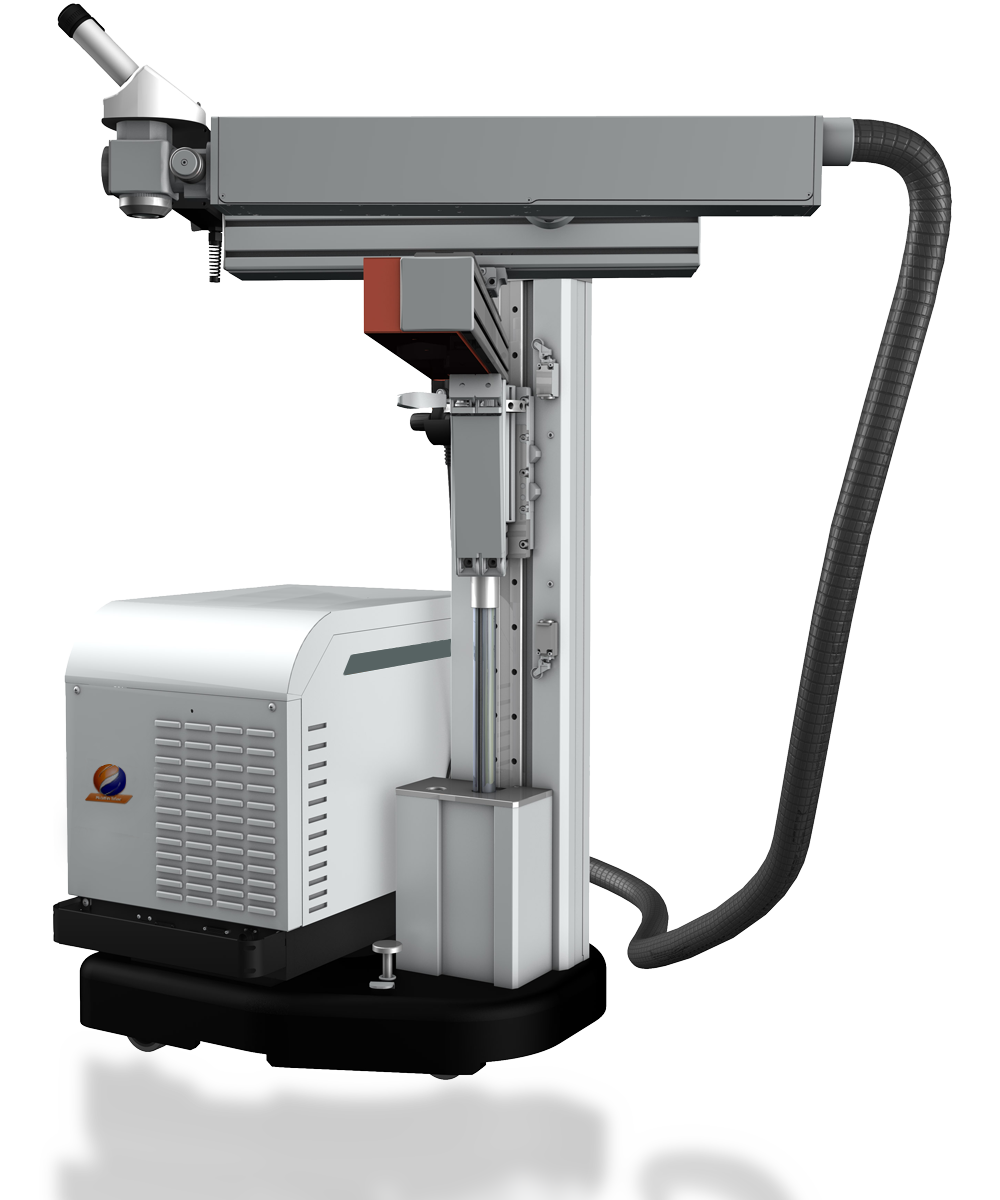

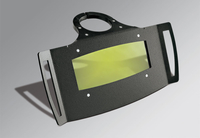

HTS MOBILE

Versatility meets Stability

Laser technology for big and small workpieces

Highlights

- Autofocus system (optionally)

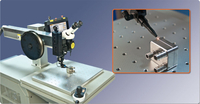

- Motor traverse in X/Y/Z and R-axis!

- Teach-in function

- Digital joystick

- Direct laser beam source

- High quality rail system by THK

Extremely powerful, reliable and adaptable

The HTS Mobile combines flexibility and stability in servicing and repairing small precision components for the aerospace industry as well as large diecasting molds that are, for example, required for the manufacturing of automobile bumpers. The mobile laser system can easily be moved and fixed in a stable position by means of the brakes. The movement of the axes permits a very long traverse range, which is accomplished via the joystick. Optionally the system can be supplied with either an analogue joystick or digital joystick both equipped with Teach-in control. The welding position can be determined at a precision of 0.1 mm. The ideal solution for big or recessed workpieces

Low vibration

As a result of the swiveling arm and the mobile resonator, the welding of large components is virtually independent of geometry and position! In the process 3D geometries are easily mastered. The stable and rigid construction method gives you the opportunity to extend or raise the standardized swivel arm. To achieve an even greater traverse range.

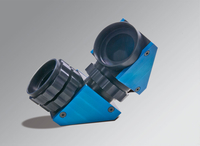

The productive laser concept

No angle will remain concealed with the optic extension and the 360° swivel optic as a supplementary module. The laser beam is guided to the welding position accurately to the millimeter.

The fast assembly and disassembly of the HTS MOBILE as well as long traverse ranges for the axes minimize the overall expenditure during the process of tools or molds.